In a book that I wrote about golf cart repair, “Electric Golf Cart Repair 101 (and a half)”, I began the first chapter with a statement that a “Meter is a Must”. That book was written with the “do it yourself” mechanic in mind and the statement was certainly true. However, even if you never intend to repair your golf cart (beyond the very simplest of situations), there are some very interesting things that can be learned about the condition of the cart with a simple test or two with a very inexpensive meter. You don’t need to be an electronics genius or even very mechanically inclined to have some fun with a meter and get a feel for what is going on with things. By far and away, the most important thing that you can take a look at is the condition of the batteries, but there are some other things you can do with a meter that will be helpful also, so let’s take a look at a meter and see what it is all about.

In the process of working on golf carts for people over a period of years, I was surprised to see how many people seemed intimidated at the mention of using a meter. In many cases, I could have told the customer what was wrong with their cart as well as what needed to be done about it over the phone, if I could have just gotten them to make a simple meter reading and tell me what they saw. It was as if the mere mention of a meter separated our worlds from one another.

Because using a meter to take simple readings on a golf cart is so easy, and because purchasing a meter is so inexpensive, I decided to write this article to shed some light on it, even for the least experienced “would be” meter reader. Keep in mind that this article is NOT about how to use a meter in EVERY imaginable situation regarding golf cart repair. Rather, it is intended only to give you the very basics of how to use a meter to make a DC voltage reading and to provide a couple of practical examples of using the meter while working on a golf cart. To learn more about what can go wrong with a golf cart and how to troubleshoot one, I recommend the book “Electric Golf Cart Repair 101 (and a half)” which is available from Amazon at this link: Book: Ronald L Staley: 9780578560557: Amazon.com: Books

In “the old days”, meters were mostly “analog” meters. That meant that they had a needle that moved over the printed scales of the face of the meter. Each scale selection of the meter had its own representative markings on the face of the meter, and the operator had to be careful to be sure that the markings he was using for his reading were the correct ones. It could get very confusing for a beginner or even a veteran meter reader. Thank goodness, most all of the newer meters are “digital” and simply show the numbers that represent the reading on an “easy to read” display. The meters are usually referred to as “DMMs”, which stands for Digital-Multi-Meter. The “multi” part indicates that the meter can be used for more than just DC voltage readings (like the ones we are going to use it for). They can usually also read AC voltages, resistance in ohms, current flow in amperes, etc., but we don’t need any of that to do the simple tests we are going to be talking about in this article.

So, let’s take a look at just what a modern day, inexpensive meter looks like. In the book I wrote (as mentioned above) I used a very inexpensive meter as an example. The meter came from Harbor Freight (HF) and was a model 90899. Then I discovered that I had another meter just like the 90899, but it had a number of 98025. The only difference I could see was that the power switch was yellow instead of red. So, apparently, they “play” with the identification numbers some from time to time, but just so it does the job, it’s OK. I just went to Harbor Freight to see what is their current “cheapo” meter is and sure enough, it was still the same meter and even still had the 90899 as an identification number on it. Its price had gone up from about $5 in 2019 to about $10 now, but if you learn how to use it, it will be the best 10 bucks you ever spent on your golf cart. Now, if you are fortunate enough to have a nicer more expensive meter, that’s even better, but it will still work roughly the same way. The readings might be a little more accurate with a more expensive meter, but that is not necessary for what we are going to do with the meter in this article. Most of the time, I use a fairly expensive “Fluke” meter when I am troubleshooting, but that is just because I have it and it’s convenient. The HF meter will do just about anything the Fluke will do. It may be a little less accurate and a little slower to take a reading with, but it will suffice.

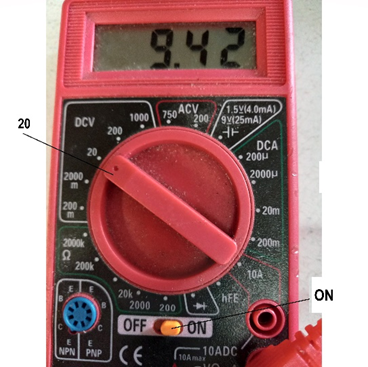

The HR 90899 looks like this:

We’ll now go through what you need to do to use it. The meter comes with two leads (probes). One is black and the other is red. The black one needs to be plugged into a “hole” at the bottom right of the meter. The correct hole is labeled “COM”, which stands for common. For all of our “basic tests”, that’s where the black probe will stay connected. If you are using some other brand of meter, there will still be a place for the black lead. It might be labeled in some other way (“negative”, or “-“ or something else), but you will figure it out. The red lead will go into the hole just above the “COM” hole. It is used for voltage tests (V), ohm tests (Ω), and low value current (mA) tests, which cover all that we will be using in our basic testing. The hole is labeled V Ω ma. Once again, if you are using some other brand of meter, the hole might be labeled in some other way (“+”, “positive” etc.), but you want the hole that is for taking positive DC voltage readings. Our meter now, with the leads plugged in, looks like this:

All of the tests that we are going to do in this part of the article, will be “voltage” tests. So, the next thing we need to do is to get the meter turned on and the right “scale” selected. The reason there are so many scales that can be selected, is to make the readings more accurate. If you measure a very low voltage on a very high scale, the reading’s accuracy is drastically affected. You would still get a “ballpark” reading, but it won’t be as good as it would be, if a lower scale had been selected. Meters of all kinds, even the old “non-digital” type with the needle that moves across the front of the meter with a reading, tended to get better readings when used at nearly full scale. And these newer “digital” meters are the same way. In our case, the highest voltage we would ever need to test would be that of the entire battery back. Depending on the model of cart you have, that would either be 36, or 48 volts. On this particular meter, the scales for DC readings jump from 20 to 200, so I must pick the higher one of 200. That means that this scale should never be used to test for a voltage higher than 200 volts. We don’t have to worry about that with our golf cart. However, it would be better if we had for instance a 60 or even 100-volt scale, but we don’t, so we will have to settle for the 200-volt scale. Having worked on these things for many years, I can assure you that the meter will be accurate enough for our purposes on the 200-volt scale, so don’t worry about it.

So, to kind of get the “hang of it”, we’ll set the meter up to measure the voltage of a 9-volt battery. First, we need to turn the meter “ON”.

I’ve pointed out the “ON” switch for this particular meter in the picture above.

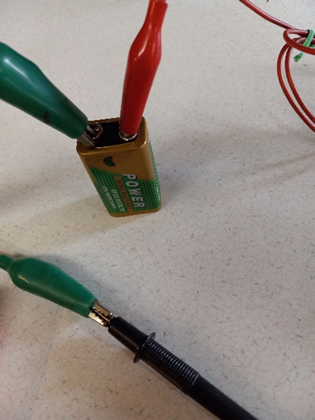

Next, we need to select the proper “function” and “scale”. In our case, as discussed above, we will be measuring DC voltages (direct current) and we want to select the lowest scale for the range of voltages we think that we are going to observe. Since we are going to measure a 9-volt battery, we will select the 20 DCV scale. In the picture above, I’ve pointed out how that will look. Of course, it would be nice if the meter had a 10-volt scale, because then we would be measuring closer to “full scale” and thereby ensure better accuracy, but in our case, our “cheapo” meter only has a few scales, so we will pick the one that is closest to the approximately 9 volts that we expect to measure, and that is the 20-volt scale (20 DCV). Notice in the picture that there is a small “dot” on the end of the “pointer” that is rotated to make the function and scale selection. That is important, because if you have the other end of the pointer aimed at 20 instead of the “dot” end, it won’t work. Next, we need to attach the leads with the probes on the connectors of the battery. You could just hold the probes on the terminals by hand, but it is very hard to keep them there while you are making a reading, so, I recommend the use of some jumpers that have “alligator clips” on their ends. You’ll see in the next pictures, that I have simply connected one end of the jumpers to the end of the probes and the other ends to the point where the test is to be made:

On the side of the 9-volt battery, there is “-“ and a “+” to indicate the negative and positive connectors. Of course, the black one will go on the “-“ and the red one will go on the “+”.

One of the first things you will notice is that when you first connect the meter to the battery, the meter will appear to go “nuts” for just a second. You need to let it settle out for a second or so until you get a steady reading. This has to do with what is called the meter’s “sampling rate”. The meter is actually looking at the voltage of the battery every few milliseconds and then displaying an average of what it sees on the display. This is where a more expensive meter has somewhat of an advantage. It will have a much faster sampling rate and therefore come to a stable display much quicker. But that is no “big deal”. Just be patient with the “cheapo” meter and give it a chance to settle out before you trust its reading.

As indicated by the pictures, if the 9-volt battery is good, the meter should show something above 9 volts, like 9.42 or so.

Just for a comparison, I hooked up the Fluke 115 that I used to the same test situation below:

As you see, everything is still the same: a red lead connected to the positive of the battery and a black lead connected to the negative connector of the battery. The Fluke reads about a hundredth of a volt higher than the “cheapo” meter, but for what we are doing, we are certainly not going to worry about a few hundredths of a volt one way or the other.

We are about to use the meter to do some testing on a golf cart, but before we do, we need to figure out what kind of readings we should expect to see.

This leads to another discussion that we need to understand about batteries if we are going to understand the readings that we get from them in a golf cart. A 6-volt battery really isn’t a 6-volt battery at all. Neither is an 8-volt really an 8-volt battery. Neither is a 12-volt battery really a 12-volt battery (at least most of the time). Notice our good 9-volt battery didn’t read 9 volts. It read around 9.4 volts. That may not sound like much difference, but I hope to convince you that it really is.

Golf cart batteries are actually constructed by placing 2-volt “cells” in series. This is a cone inside the packaging of the battery, so you can’t see it, but that is what is done. Likewise, a 2-volt cell isn’t really a 2-volt cell (when it is charged to its maximum). When properly charged, a 2-volt cell will (under ideal circumstances) read around 2.15 volts. By the time it is discharged down to 2 volts, it is almost totally “dead”. So, if we connect 3 “2-volt” cells in series, to produce a 6-volt golf cart battery, when properly charged, it should read around 6.45 volts. As the battery ages, it doesn’t charge back up to quite as high a charge state, so we usually expect to see a fully charged 6-volt golf cart battery read around 6.33 volts or so. That means that if we have 6 of them in series to create a 36-volt cart, fully charged the “battery pack” as a whole, should read around 37.9 volts, NOT 36 volts.

Likewise, a 48-volt cart, when fully charged should read about 50.64 volts. If it has 6 8-volt batteries, that’s 2.11 volts per cell multiplied by 4 cells per battery multiplied by 6 batteries (2.11 x 4 x 6 = 50.64). If it has 4 12-volt batteries in it, that’s 2.11 volts per cell multiplied by 6 cells per battery multiplied by 4 batteries (2.11 x 6 x 4 = 50.64).

The following chart is something that I put together and represents what most golf cart manufacturers characterize as the charge to discharge cycle of the batteries as the golf cart is used. The information varies somewhat from manufacturer to manufacturer, but I have sort of averaged their information out to get an overall picture of how it works.

| State of Charge | One Cell | 6-volt (36-volt pack) | 8-volt (48-volt pack) | 12-volt (48-volt pack) |

| 100% | 2.1 and over | 6.3 (37.8) and over | 8.4 (50.4) and over | 12.6 (50.4) and over |

| 90% | 2.08 | 6.24 (37.44) | 8.32 (49.92) | 12.48 (49.92) |

| 80% | 2.07 | 6.21 (37.26) | 8.28 (49.68) | 12.42 (49.68) |

| 70% | 2.05 | 6.15 (36.9) | 8.2 (49.2) | 12.3 (49.2) |

| 60% | 2.03 | 6.09 (36.54) | 8.12 (48.72) | 12.18 (48.72) |

| 50% | 2.01 | 6.03 (36.18) | 8.04 (48.24) | 12.06 (48.24) |

| 40% | 1.98 | 5.94 (35.64) | 7.92 (47.52) | 11.88 (47.52) |

| 30% | 1.95 | 5.85 (35.1) | 7.8 (46.8) | 11.7 (46.8) |

| 20% | 1.93 | 5.79 (34.74) | 7.72 (46.32)) | 11.58 (46.32) |

| 10% | 1.88 | 5.64(33.84) | 7.52 (45.12) | 11.28 (45.12) |

| 0% | 1.75 | 5.25 (31.5) | 7 (42) | 10.5 (42) |

If we start at the top on the left side, the term “state of charge” is used to describe how much usable energy is actually left in the battery at any given time. Obviously, when fully charged, the battery is said to be at a 100% state of charge. But what happens when the battery is used is kind of interesting. If you look at the column that represents a 36-volt cart with 6 6-volt batteries in it, you can see that the battery doesn’t go from 6.3 volts at 100% down to 0 volts at 0%. Not at all! In its whole cycle of discharging, it only goes from 6.3 down to 5.25. And that would be taking the charge level of the battery clear down to 0%. Most manufacturers recommend that you never go below the 50% charge state, which is about 6 volts. So, you are really working with from 6.3 (or just a little higher) down to 6 volts as the entire variation in the battery’s voltage over a normal charge-discharge cycle. In some support literature from battery manufacturers that I have read, they say not to go lower than 50 to 80%, but from experience, I can tell you that taking the batteries down lower than 50% shortens the lifespan of the batteries drastically.

Since we are dealing with such small differences in voltage representing such large variations in state of charge, the DMM is a much better tool than one of the old analog meters. It was hard to detect such small differences with the needle above the markings on the display. Just a “needle’s width” of movement might indicate the whole difference between two different readings. Thank goodness for DMMs.

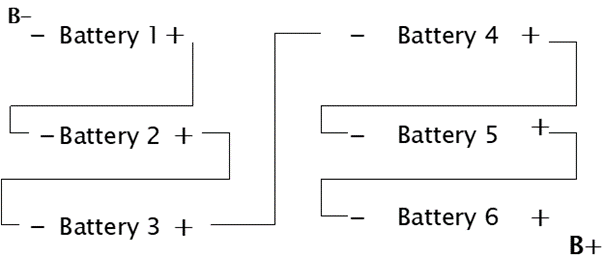

So let’s get practical and start doing some reading on a “hypothetical” golf cart. The first thing we will look at is the voltage across the whole battery pack. Since the golf cart batteries are “hooked” in series, we have to determine where they “start’ and where they “end”. Here is a drawing of 6 6-volt batteries hooked in series to form a 36-volt pack:

The way that the batteries are placed in the cart’s battery box varies from model to model. Battery 1 could be anywhere (physically) in the box, and therefore, so could Battery 6 and everything in between. Their placement is made to accommodate the shape of the box and the series string could start and end anywhere. You have to figure out how it is arranged on each cart you are going to make measurements on.

Our intention is to take a reading with our DMM “across” the entire pack. That means that our negative probe will be connected to the spot marked B- in the drawing. Notice, that is the negative post of what is called “Battery 1” in the drawing. Then, with our positive probe, we want to connect to the spot marked B+ on the drawing. Here is where the “jumpers” that I mentioned earlier will come in handy. It’s very difficult to hold two probes on two different places at the same time and get a reading. Plus, lots of times the probes want to “slide around” while you are waiting for the reading to “settle” out, as I mentioned earlier. Often times, I will clip the negative probe to B- (using the jumper with the alligator clips on it) and just use the positive probe to look around for readings. Most of the time (not always), the readings will be made with the negative probe on B-, so I just clip it on to B- and leave it there.

In order to locate B- and B+, you will notice that there are “large” wires and “smaller” wires connected to various places in the battery compartment. The larger wires are usually either 6 or 4-gauge wires and are connected between the batteries to form the series circuit. These larger wires also connect the batteries to other major components in order to supply the large amount of current required from the batteries to run the motor and propel the cart. So, first off, we want to connect our B- probe (preferably with the jumper with the alligator clips) to B-.

As indicated by the diagram, the batteries are wired in series, starting with Battey 1. The negative post on Battery 1 is the first place that we need to locate. Battery 1 will be the only battery in the pack that DOESN’T have a large wire on its negative post that goes to another battery. Its negative post is (again) B-, and it will still have a large wire connected to it, but it doesn’t go to any of the other batteries. It goes to other important places, but it will not have a wire going to another battery. Another thing that might help locate B- is that MOST of the time it will have (in addition to the 6 gauge wire) a fairly large wire that goes over to the charger receptacle. This wire is usually about a 10-gauge wire and will be connected to the terminal of the charger receptacle that has a “-“. There are some carts that are wired differently than this, especially 48-volt Club Cars, but most of the rest of them do. The B- terminal will usually have at least one other much smaller wire (in the order of perhaps 16 or 18-gauge) for the purpose of connecting low voltage (12-volt) appliances like lights, horns, etc. also. I think of the B- point as the “beginning of the chain” of batteries. Once you have located it, you should be able to go to its positive post and see that it goes to the next battery in the chain. In keeping with our “series” configuration, it will of course go to the next battery’s negative post. Then the second batterie’s positive post will go over to the next battery in the chain’s negative post and so forth. Get the pattern?

If you keep on tracing the “chain”, when you get to the last battery, its positive post will be what we call B+. That is the highest voltage point in the chain. It will also be recognizable in that its positive post (B+) will not go to any other battery. Like B-, it will have a 6-gauge wire connected to it, but it won’t go to any of the other batteries. It will also usually have a little bit smaller wire (10-gauge or so) going to the positive connector of the charger receptacle, just as B- had one going to the negative connector. B+ will also probably have smaller wire or two (16 or 18-gauge) that provide connections to other things.

Well, hopefully you now have found B- and B+ and we are ready to do some testing. Of course, our test results are going to depend on what the state of charge the battery pack is at. So, a good place to start, in my opinion, is to put the cart on the charger (assuming it is working properly) over night and start testing when the battery pack is (or should be) at 100% state of charge.

There are really two different ways that you need to learn to test batteries. The first is what I call “static” testing, and the other is what I call “dynamic” testing.

Static testing of the batteries is when they have no “load” on them. They are just sitting there, connected up, but the cart isn’t being driven. A quick note here should be made mention of. Even when the cart isn’t being operated, on most systems there is “technically” an extremely small load on the batteries to keep the motor speed controller in a “ready” state. However, the load is so small, that we will ignore it all together. It won’t affect our readings to any meaningful degree.

So, our first test will be a static test of the battery pack’s voltage. It important to note at this point that in order to get a good static reading across a fully charged battery pack that the cart JUST came off of the charger, they must be allowed to “rest” for a while (around 30 minutes) before the reading will be meaningful. The charger has to use a voltage considerably higher than that of the battery pack in order to “pull” the pack’s voltage up. So, for instance, a 36 volt pack that just came off of a charger that just shut off, might read clear up around 40 volts or so. But, once the charger is disconnected and the batteries are allowed to sit for a while, the voltage will drop down to the actual dynamic reading that we are looking for. So, the cart should have its key switch turned off, the Forward/Reverse switch in the neutral position, and of course, the accelerator in the “resting” (untouched) position. We expect to read around 36 or 48 volts (depending on the type of cart that you have) so now, we need to select the proper scale on our meter to accommodate the test. Remember, we would like to use the “lowest” scale that we can (without overloading it) in order to be as accurate with our test as we can be. On our “cheapo” meter, our scales jump from the 20 DCV scale all the way up to 200 DCV, with nothing in between, so we don’t have much choice but to use the 200 DCV scale. Yes, it would be better if we could use a 100-volt scale or a 75-volt scale or something closer to the roughly 50 volts we are looking for, but for what we are doing, the 200 VDC scale will be just fine.

So, now it is time to connect the negative probe of the meter to B-. This, again, is where the jumper with the alligator clips comes in handy. Next, with the meter turned on and the 200 VDC scale selected we simply touch the positive probe on B+ (or clip it on with the jumper, and BINGO, that’s our static reading.

What does the reading mean? Well, we know from the chart near the beginning of the article that if the battery pack is fully charged, we should read around 37.8 volts or higher for a 36-volt cart or 50.4 volts or higher for a 48-volt cart. What if it doesn’t?

Let’s say that you have a 36-volt cart and your static reading is way low (31 volts or so). What might that be all about?

Well, we know it’s too low, so here are the possibilities:

The battery charger isn’t working correctly so it didn’t really charge the battery pack to its maximum potential

The batteries are shot and won’t accept a charge to the correct level

One battery in the pack is bad and not allowing the pack to receive its proper charge (could be more than one, without being all six)

The wiring between the batteries is faulty and adding resistance to the current flowing through the charge path

We’ll start with the charger. Most chargers today that are used on 36-volt carts are “automatic”. That means that when you plug them into the cart, the charger “looks” at the battery pack’s voltage and “makes a decision” about whether to turn itself on or not. On 48-volt Club Cars, we have a different situation. We’ll discuss them in just a moment. Back to the typical 36-volt cart, generally, if the voltage doesn’t come up to about 70% of the 36 volts that the cart is named for (25.5 volts), then the charger assumes that something is wrong that needs to be taken care of before it is willing to try to charge the pack. So, at this point, you would have to investigate whether the charger seemed to go through a normal charge cycle when it is plugged into the cart or not. We’ll go deeper into the possibilities of why the charger might not come on a little later, but for now, if our static battery pack reading was 31.6 volts, it should be high enough to bring the charger on (it’s above 25.5 volts). So that would indicate that the charger itself is likely to be at fault. You’d be surprised to know how many times it is because the charger is plugged into the cart, but not into a 110-volt source. I live in Florida, and many people here are gone for the summer and when they return for “the season”, the unused cart has simply let the battery pack’s voltage drop below the 25.5 volts so that the charger won’t come on. In many cases, it is easier to charge each battery individually with a 6/12 automotive charger enough to get their combined voltage over the 25.5 volts and then turn the charging over to the cart’s charger.

The 36-volt cart’s automatic charger also monitors the charge state of the battery pack during the charge process and shuts itself off when it “thinks” that the job is done.

I mentioned the 48-volt Club Car being different and it is. Instead of letting the charger make the decision about whether to come on or not, as well as when to shut off, the Club Car incorporates a computer to do the job. It is referred to as an On Board Computer (OBC), but it basically does the same thing as the 36-volt cart’s automatic charger. The cart’s static voltage reading for the battery pack when fully charged should be the 50.4 volts (or so) that we mentioned before.

Which leads to the next possibility.

If the carts batteries are old or defective and just won’t accept enough of a charge to get the pack’s voltage above the 25.5 volts to turn the charger on, or to make the OBC “happy” on a 48-volt cart, then it’s time for new batteries. It could, however be that just a couple of the batteries are causing the problem. So, at this point we would need to check the static voltage of each of the batteries individually. This is really the same as testing the pack’s voltage except that we need to move both of the probes from battery to battery and use a more appropriate scale on the meter. Going back to the diagram above, the first battery that we will test individually is Battery 1. For this, we will still have the negative probe on B-, because that is the negative post of the first battery we are going to test. However, instead of leaving the positive probe on B+, we will move it to the positive post of Battery 1. The scale that we will select is 20 DCV (instead of 200 DCV) because it is closer to the voltage that we expect to find (around 6 or 8 volts) each battery to read. Then the next battery we will test is Battery 2. For this one, we simply move the negative probe’s alligator clip to the negative post of Battery 2. Then, we connect the positive probe to the positive post of Battery 2. Then we just repeat the process for each of the other batteries (Battery 3, 4, 5 and 6). While doing this test of the individual batteries, it is not necessary to remove any wires. Just go from battery to battery with the meter.

Now what we would like to see is a consistency of readings for the batteries, and if they are all good (statically), they should all be in the neighborhood of the 6.3 (for 36-volt carts) or 8.4 (for 48-volt carts). If you have a bad battery (statically) it will stick out like a sore thumb from the rest. It could even read 4 volts or 2 volts or some other crazy number, depending on what is actually wrong internally with the battery. And that’s exactly what the meter is for. To help find something that isn’t right.

During this individual testing of the batteries, it’s a good time to look the wiring over very closely that goes between the batteries and also those that take off from B+ and B- and go off to wherever they go. Lots of battery pack problems are attributable to cable problems. They “live” in an atmosphere of sulfuric acid vapors, and the cables are notorious for corroding.

The next test that we will discuss is one that I refer to as a “dynamic” test. What usually leads to a dynamic test is a situation where the batteries have been tested statically and seems to be OK, but the cart has a problem. The problem is either poor performance, limited top speed, won’t climb hills, etc. These things can (and often do) indicate a battery’s inability to maintain its voltage under a load. That is exactly what dynamic testing is all about.

OK. I know you have heard of load testing with a “load meter”, but that has some limitations. A typical load tester is the type you can buy at your local auto parts supplier for around $20 or so. The load tester is really just an analog volt meter, but it has a “load” (just a resistor) built into it. You can hook the load tester across any one of the individual batteries and then when you flip a switch, it puts a resistive load across the battery. Most load testers are only designed to be used with one single battery at a time. It has scales marked on its “face” so that it can be used for 6 and 12-volt batteries, but you CAN use it on 8-volt batteries, you just have to use your imagination a little figure out what markings on the face would be proportional for 8 volts instead of 12 volts. You only hold the switch for a few seconds and watch the load meter’s needle on its scale. The theory is that if the needle only drops so far, the battery is good. If it drops further than it should, then the battery is bad. The problem is that the load that the meter puts on the battery isn’t consistent with the load that the golf cart might represent under certain circumstances. And the length of time that the load test is used might not be consistent with the amount of time that a cart takes getting up a hill or even just being used with several passengers, etc. I have always preferred to use the golf cart itself as the load tester.

Now here’s the challenge. In order to do a dynamic test of the batteries using the cart as the load, we’ve got to be able to read the meter while we are driving the cart. At first that may seem a little crazy, but it is actually fairly easy to do. You MUST, of course, have the jumpers with the alligator clips on them (both the negative and the positive probes). And the trick is to be able to connect the alligator clips to the posts of the battery or batteries that you want to test and then be able to route the test leads from the battery box to where you can set the meter on top of the seat where you can see it while you or someone else is driving the cart. It’s really NOT THAT TOUGH to do. The seats on different models vary, but there is always SOME way to do it. I’ve used a small piece of wood to keep the seat from completely closing down on the wires on some of them. As a matter of fact, when I had the golf cart repair business, I “crafted” a “half seat” out of plywood that would let me drive the cart and still have access to the batteries. It was especially useful for watching the motor and clutches while driving a gas driven cart. Anyway, you’ll find a way to route the wires to where the meter can be observed while you put the cart through its paces.

Many people think it would be OK just to raise the back end of the cart to let the tires spin but that DOES NOT WORK. Doing that takes away the LOAD that the system experiences from the weight of the cart, its “rolling” resistance, the effort it needs to push the cart up a hill, etc.

So, let’s start with probably the most useful and often used dynamic test. That is where we’ll look at the voltage of the whole battery pack. In this case, the negative probe needs to be connected to B- and the positive probe needs to be on B+, just like when we did the static test of the whole battery pack.

Let’s assume that you are testing a 36-volt cart. With the probes attached to B- and B+, the proper scale selected on the meter (on our “cheapo” meter it’s the 200 DCV range), and, of course, with the meter turned on, we are ready to do our test. Before we put the cart in motion, our reading will be the static reading of around 37.8 volts, provided the batteries have been fully charged.

Now comes the “fun” part. While driving the cart, you watch the meter to see what happens to the static reading under dynamic circumstances. When you first “take-off”, the 37.8 volt reading should drop some, but not a bunch. A typical take-off on a relatively flat surface should not see the meter go much below 36 volts or so and then when the cart gets up to speed, the reading should “crawl” back up toward the 37.8 volt reading again. If you took off by slamming the accelerator all the way to the floor and then just left it there, you would see the meter go toward 35.5 volt reading at first, but as the speed came up to maximum, the meter should come back up. It won’t get quite back up to the unloaded reading of 37.8, because there is a load on the pack now to maintain the “wide open speed”, but it will come back up toward 37 to at least 36.5 or so. Now, remember, our “cheapo” meter has to kind of stabilize out on a reading. So, it might get a little confusing at first, but you will get the “hang of it”. Just wait until you see a “consistency” of readings in the situation you are in that make sense and you’ve got it. I’ve used the little “cheapo” meter for the dynamic tests many times, and they work just fine.

The next thing I’d do is to find a reasonable hill to climb. It doesn’t need to be a “crazy steep” hill. It just needs to represent something that you would normally encounter driving the cart where you usually drive it. I live in Florida, where we don’t generally have any very big hills (unless they are manmade on a golf course or something). As you watch the meter this time, the reading will go even a little lower than on flat ground for a while. It might even get down in the 33 or 34-volt range, but once again, as the cart comes up to speed and eventually gets over the hill, the reading should crawl back up to the 37 volt range and stabilize out there.

So, let’s say that the meter drops (on take-off) way down below 32 volts, and then is slow to come back up as the cart gains speed, or never does come all of the way back up in the 37 volt range. Then you know that you have a problem. It could be that “all” of the batteries are tired and need replaced or it could be just one or two of them.

Here is where you will want to do a dynamic test of each individual battery. As you watch the meter, while repeating the test drive just as before, you will be looking for one of the batteries that is “falling out” as we call it. Believe it or not, a battery can act OK under a small load or no load but “croak” temporarily when under normal driving. They can even come back to life and act normal for a while and then act up again later. Obviously, you have to do the dynamic test on each battery, one at a time. You just put the negative probe on the negative post of the battery being tested and the positive probe the positive post, and away you go.

That is the beauty of doing the dynamic testing with the cart, as opposed to using some sort of AN external load tester. You get to see what is happening to the voltage of the battery pack as well as the individual batteries under normal operating circumstances, not just while the switch of a load meter is being held down.

I remember when I was first trying to learn about golf cart repair. Of course, right off the bat, one of the first carts I got to work on had an unusual intermittent problem. I’d be driving along and everything was just fine, then all of a sudden, the cart would stop. Sometimes it would make a few “lunges” before it stopped, but eventually it would stop altogether. By the time I could get a meter out and start “looking around” at stuff, sure enough, it would start working again as normal. I came from a strong mechanical and electronics background, but I had never worked on anything that had this many of these “specialty” type of lead acid batteries in it. The golf cart lead acid batteries are quite different than the lead acid batteries used to start a car. I was used to having a battery just get weaker and weaker until in “died” and that was it. You’d put a meter on it and it would show very low voltage and you would replace it and be done with it. I just couldn’t imagine a battery “coming and going” and “coming back” again. This was a new one to me. I had experienced lots of intermittent issues with all kinds of equipment involving both electrical and mechanical issues, so I had some great ideas about what could be causing the problem. Things like bad wiring connections, bad throttle position sensor and things like that. I even had the “brilliant’ idea on this cart that the problem might be a brush stuck in its guide inside the motor or a brush that had worn to the point that sometimes it didn’t touch the commentator. That one cost me about a day’s work for nothing (still had the problem). Next, I very “cleverly” pronounced the motor speed controller as the culprit (another waste of time and a bunch of money). Sure enough, it turned out to be that one of the batteries was just dropping out whenever it wanted to and then coming back before I could catch it. Something you would never pin down with a load tester. So, trust me, I learned THE HARD WAY about what an intermittent battery can do. If I had been doing a simple dynamic test of the battery pack as my first step, I’d have seen the pack’s voltage drop off when the cart died. I would then have known then to do the dynamic test on each individual battery to pin down which one was “killing me”.

So, now let’s find some other things we can use the meter on.

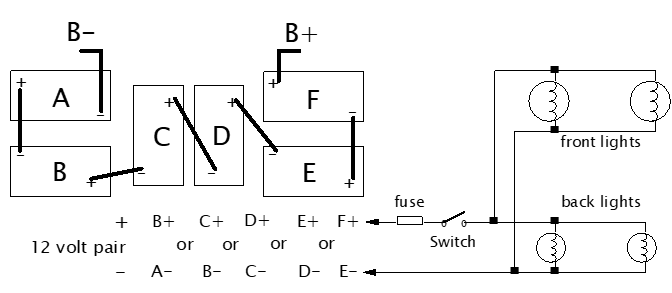

Another common thing that the meter could be used for is to troubleshoot 12-volt appliance issues. There are several ways to hook these devises up, so we’ll start with the “old fashioned” way.

Let’s take for example, an older cart with 6-volt batteries. Since the batteries are 6 volts each and our appliance (we’ll say it is a set of lights) needs 12 volts to operate, it makes sense to just take two batteries that are wired in series anyway and “steal” the 12 volts from them. But there are a couple of things to remember. One is that there is a “Golden Rule” that must NOT be compromised. That is this: DO NOT EVER (under any circumstances) elect to use the chassis of the cart as one of the conductors to supply energy to the accessory. When people do this, they are creating a major potential for problems. Once you anchor ANY post of ANY battery in the Battery Pack to the chassis, all other posts represent a threat if accidentally shorted to the chassis. Suppose you drop a wrench in the battery box while working on something. If it lands between ANY of the other battery posts and the chassis, you may have turned your cart into a fairly good, although short lasting, arc welder. The idea of using the chassis as a ground comes from the automotive trade where you are only dealing with 12 volts, not 36 or 48 volts. The higher voltage can actually “weld” pieces of metal together if something falls in the wrong place. So, the chassis MUST remain isolated from ALL of the circuits in the cart. Hopefully, whomever wired the appliances up in your cart observed this rule.

The following is a diagram of a typical 36-volt (older) cart’s battery layout. Since we only need 12 volts, whomever wired up the lights on the cart could have selected any two adjacent batteries (next to each other in the string) to supply the 12 volts to the lights. So, we’ll have to look around to figure out which two were used. As indicated by the diagram, there are five possible combinations that could be used. Batteries A&B, B&C, C&D, D&E, or E&F. Let’s assume that the “wirer” used E&F. To trouble shoot through the circuit, the negative post of E will be where the negative probe of the meter will be connected. The rest of the circuitry through the fuse, the switch and the lights themselves will all be “with reference” to E’s negative post. So, if you put your negative probe of the meter on E’s negative post, you should be able to find 12 volts on F’s positive probe, the input to the fuse, the output of the fuse, the input to the switch, the out put of the switch (once it is turned on), and off to each of the lights.

This is just a simple example of using a meter to troubleshoot through a circuit. You need to find out where the negative for the circuit is located, use it as the reference point (negative probe) and then trace through the circuit with the positive probe to see where any disruption of the circuit might be.

I spent a lot more time on specific uses of a meter in the book that I mentioned before: Electric Golf Cart Repair 101 (and a half) which is available from Amazon both as an eBook and as a hardcopy. Here are the links again:

Hardcopy

Book: Ronald L Staley: 9780578560557: Amazon.com: Books

eBook

Amazon.com: Electric Golf Cart Repair 101 (and a half): Techniques, Tips, Tools and Tales eBook : Staley, Ronald: Books In conclusion, (for this article) a meter is an invaluable tool for seeing what is happening with the innards of a golf cart. Just plug the probes in the correct “holes”, turn the meter on, select the appropriate scale, connect the probes to the proper places and away you go. What could possibly go wrong? Good luck, Ron.