“Timing” is something that is very important to the proper operation of an engine. In this post we’ll take a look at the operation of 4-stroke engines in general, and then get a little more specific in our discussion, looking at a few models of golf carts and how they accomplish things.

I always think of timing as falling into two categories: the first being that of ignition timing (when the spark in the combustion chamber occurs), and the second one being in regard to the opening and closing of the intake-valve and exhaust-valves.

When we talk about timing, there are some terms that we need to understand:

Top Dead Center (TDC) refers to the time when the piston is at the top of its travel and has moved as far away from the crankshaft as it can get. It gets there twice in the four strokes that make up the 4-stroke cycle of the engine. One of those times is right after the fuel mixture that has been drawn into the cylinder has been compressed into the combustion chamber (compression-stroke) and the explosion of the mixture (power-stroke) is ready to begin. The other time is right after the remains of the explosion have been blown out of the cylinder (exhaust-stroke) and the piston is ready to suck in more fuel mixture (intake-stroke). If an event occurring during the cycle of the engine happens just before TDC, we say that it happened BTDC (before top dead center) forshort. If it happens shortly after TDC, we say that it happened ATDC (after top dead center) for short.

Bottom Dead Center (BDC) refers to the time when the piston is at the bottom of its travel and has moved as close to the crankshaft as it can get. It gets there twice in the four strokes. One of those times is right after the power-stroke has occurred and the exhaust-stroke is ready to begin. The other time is right after the intake-stroke has occurred and the compression-stroke is ready to begin. If an event occurs just before BDC, we say it happened BBDC. If it happens shortly after BDC, we say it happened ABDC.

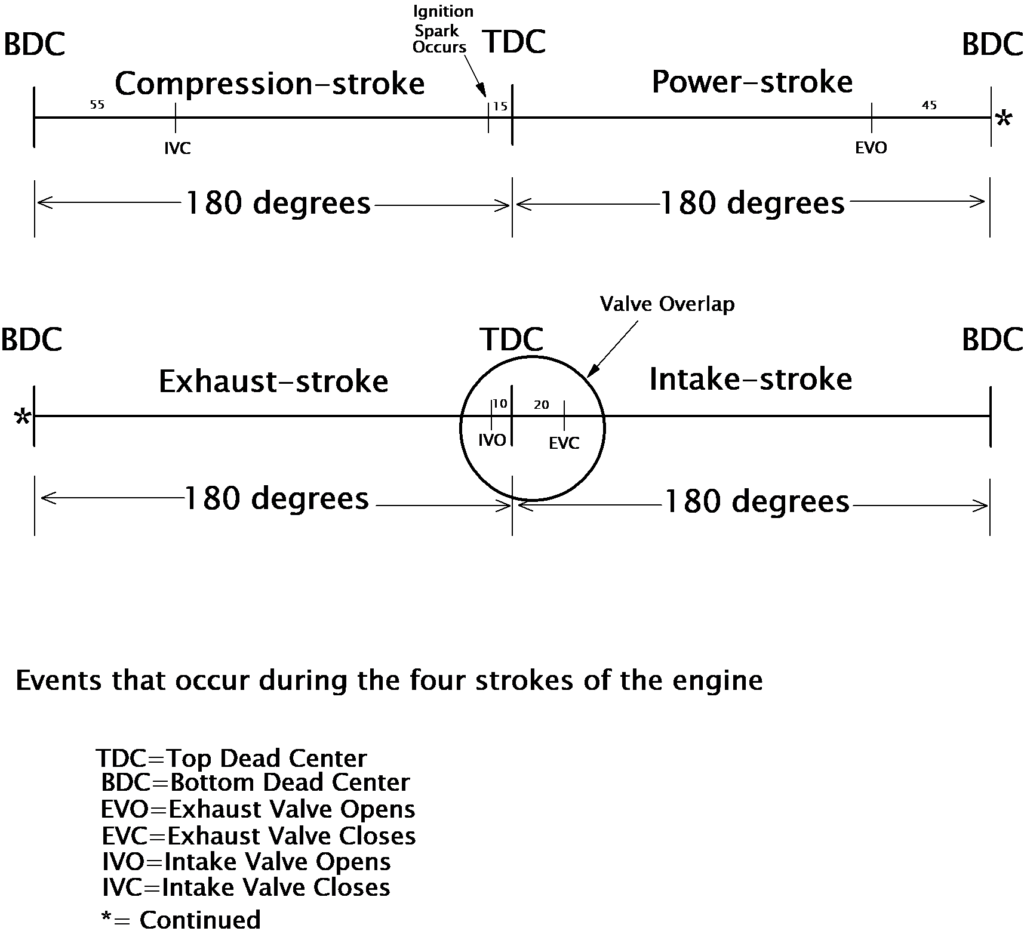

Timing degrees describes what the position of the crankshaft is in at any given time. As the engine runs, the crankshaft revolves in a circular motion. If you think of the piston moving from TDC down to BDC and then back up to TDC again, you can picture that the crankshaft would have completed one revolution. We call that one rotation 360 degrees. All of the events that take place during the completion of the four strokes involved in the engine’s 4-stroke cycle, are related to that rotation of the crankshaft in degrees. So, if we start to count degrees from the position of the piston at TDC (zero degrees), once it reaches BDC, the crankshaft will have traveled 180 degrees. Then, of course, the crankshaft will travel another 180 degrees as the piston comes back up to TDC again, for a total of 360 degrees. During the four strokes, the crankshaft will have revolved two complete times for a total of 720 degrees.

So, let’s take a look at what really happens during those four strokes. We’ll start at the TDC position with the piston at the beginning of the power-stroke. We know that both of the valves must be closed in order to seal the combustion chamber off so that power from the explosion will put maximum pressure on the piston, driving it toward the crankshaft. After the explosion, at BDC, the piston will start back up toward the top in the exhaust-stroke. For a long time, when I was a kid, I though that ignition of the explosion didn’t start until both valves were closed and the cylinder was sealed, but I was sure wrong. It ends up that the spark plug is actually ignited just before the end of the compression-stroke. That happens because it takes some time after the spark occurs for the explosion to develop (propagate) and therefore supply the maximum force to the piston. The affect is called ignition delay, and the delay is compensated for by starting the process a little early. The faster the engine is turning, the earlier the spark needs to occur, so the timing is “advanced” by some means to start things even earlier. With golf cats, the timing of this event is totally up to the way that the manufacturer has set things up and you can’t adjust it. There are a couple of popular systems that are used in golf carts to achieve ignition. One system involves a magneto and an ignitor that is either separate or part of the ignition coil. The ignitor advances the spark as the speed of the engine increases. The other system involves a pulser that detects when the position of the crankshaft is appropriate for beginning the event and also involves a separate ignition ignitor and coil. In either case, the timing of the spark is not adjustable by the user. The exact timing of the ignition event varies from model to model, but at slow speed, it usually starts at about 10 to 15 degrees BTDC (before top dead center) as the piston is coming up in the compression stroke. It may be advanced to as much as 20 or 30 degrees BTDC at higher speeds.

Another thing that happens is best observed by taking the valve cover off so you can watch the valves open and close. Also, take the spark plug out and stick a dowel (or something that is long enough not to drop down in the cylinder) down the spark plug hole and let it ride on the top of the piston and watch it go up and down as the piston travels up and down when you rotate the crankshaft by hand. This will allow you to see when the piston is at TDC and BDC. You’ll see an interesting thing happen. There is a short period when both the intake-valve and the exhaust-valve are slightly open at the same time. This period of time is referred to as the “valve overlap”. It happens at the end of the exhaust-stroke and the beginning of the intake-stroke. The idea of this is to use the momentum of the exhaust that is exiting the cylinder through the exhaust-valve to help “pull in” the new mixture that is coming in through the intake-valve during the intake-stroke. So, near the end of the exhaust- stroke, the intake-valve starts to open at somewhere around 10 degrees BTDC. As a matter of fact, in order to help the whole process out, the exhaust-valve is held slightly open around 20 degrees ATDC in the intake-stroke in order to give things plenty of time to get a good “charge” of new mixture being drawn into the cylinder.

This manipulation of the valves to create valve overlap is of course done by shaping the lobes on the camshaft to work the valves open and closed at precisely the right times. This, also, is not adjustable by the end user. It is strictly set by the shape of the camshaft and would require a different shaped camshaft to change anything with regard to valve timing.

Another interesting thing is that the exhaust-valve actually opens roughly 45 degrees BBDC at the end of the power-stroke, instead of right at BDC beginning the exhaust-stroke. The reasoning behind this is that the piston has already received the maximum amount of “push” that it will receive prior to reaching BDC, so that travel of the piston during the 45 degrees gives the piston more time to clear the expended remains of the mixture from the cylinder.

Another interesting thing is that the intake-valve is actually held open around 50 degrees after BDC during the combustion-stroke. That gives more time to complete the filling of the cylinder with the incoming mixture, before the piston has come up far enough to actually start compressing it.

The following is an attempt to describe the whole operation throughout the 4 strokes of the cycle in a little clearer form:

All of this valve timing, as I have mentioned before, is set by the shape of the lobes on the camshaft. The shape of those lobes is referred as the “grind” of the camshaft. The shape and size of the lobes also determine how high the valve is “lifted” during the operation, another important feature. Probably the wildest example of “exotic” or “radical” camshaft design is found in race cars. In their engines, power output of the engine is maximized in every way possible. You can see “fire” coming out the exhaust in many cases due to the increased valve overlap and although the engine produces lots of power in certain RPM ranges, they may struggle to even run at lower speeds.

The length of time that the valve is off of its seat (seal is broken) is referred to as valve duration. For instance, if we look at the chart above and add up the numbers of degrees that the intake-valve is open, it is as follows: 10 degrees BTDC in the compression-stroke, 180 degrees during the entire intake-stroke, and 55 degrees into the compression-stroke, for a total of 245 degrees (10 + 180 + 55). The exhaust-valve’s duration also adds up to 245 degrees. That is, of course, out of the total 720 degrees of rotation of the crankshaft for the complete 4 stroke cycle.

All in all, there is a lot more going on during those four strokes than meets the eye of the casual observer.

Ron Staley has published the following books, and you can get more information about them by just clicking HERE.

For information about books written by Ron Staley about both electric and gas driven golf carts and their repair, visit the following links.

Electric Golf Cart Repair, both as an eBook and in Hardcopy:

Book: Ronald L Staley: 9780578560557: Amazon.com: Books

Gas Golf Cart Repair, both as an eBook and in Hardcopy:Gas Golf Cart Repair Book: Ron Staley: 9798987911303: Amazon.com: Books