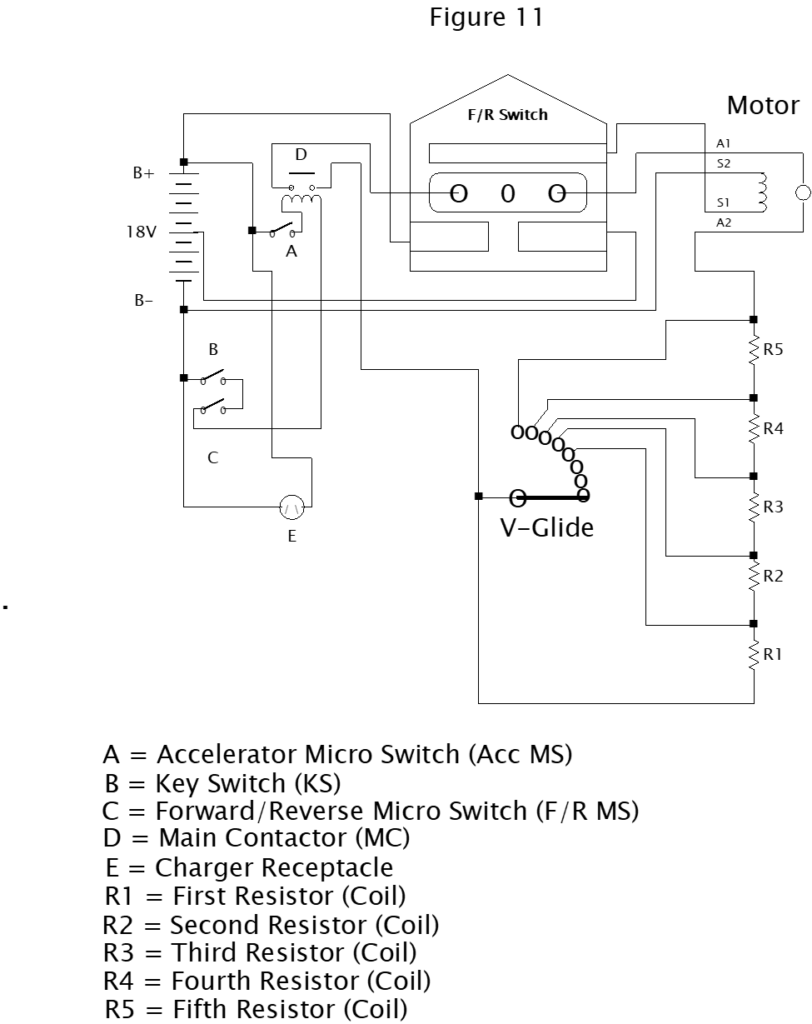

In order to get rid of most of the solenoids, but still be able to utilize the resistors for motor speed control, Club Car came up with a configuration called the V-glide (by most people). It was a big improvement over the previous system in terms of maintenance. The following is a diagram of a V-glide model taken from the book referenced at the bottom of the post (Electric Golf Cart Repair 101 (and a half).

–

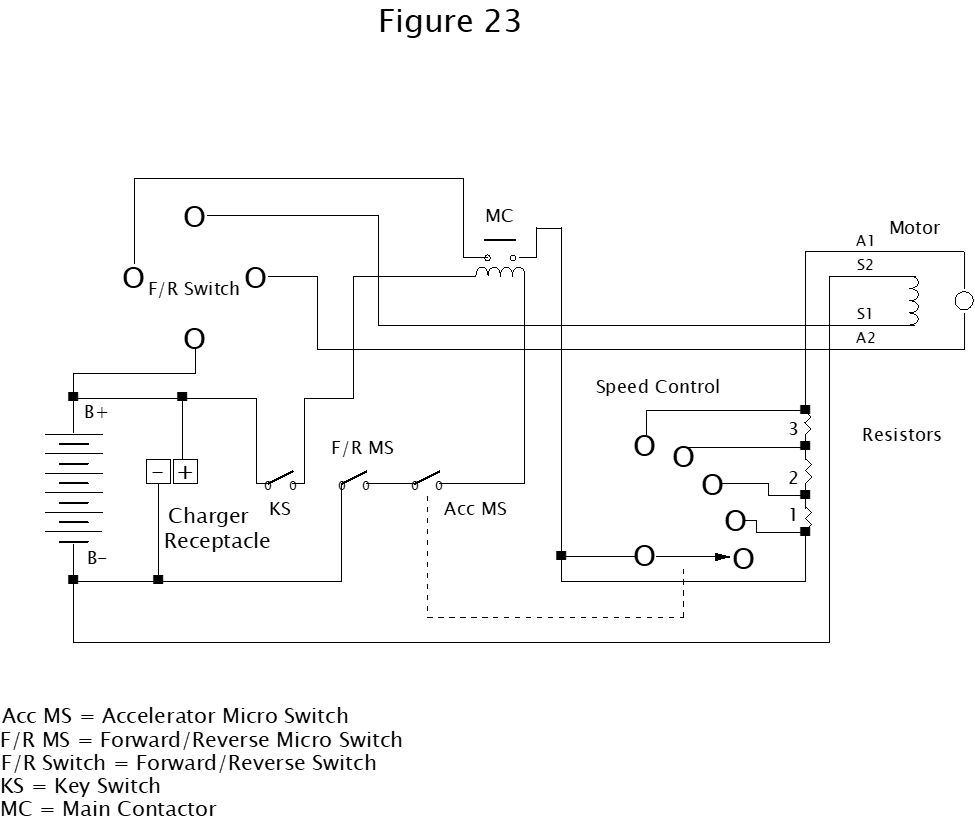

As you can see from the drawing, the resistors are still used in the circuit, but they are “added in” or “taken out” by the use of some contacts and a “wiper” in the device called the V-glide. The way that the contacts and their wiper are packaged, the unit looks like a “wedge”. Its placement in the golf cart is in front of the batteries just to the driver’s side, mounted to the frame near the bottom of the cart. You can see the large wires (6 gauge) connected to the back of the V-glide and the accelerator linkage on the front (toward the driver’s side). The wiper inside of the V-glide moves from contact to contact with the advancement of the accelerator. E-Z-Go had a similar model that is shown below (the drawing is taken from the same book):

Both systems use a solenoid to activate what I call the high energy circuitry used to drive the motor. The logic switches used to energize the solenoid are what I call the low energy circuitry. The solenoid (or what is called the Main Contactor in the drawings) is where the low energy circuit and the high energy circuit meet. The low energy circuitry allows us to use small wiring and low power-rated switches (like microswitches) in order to energize the solenoid. Once energized, the solenoid’s high energy contacts can withstand the current flow needed to drive the motor. There is a remarkably high surge of current when the motor first tries to get up to speed from a stopped (stalled) position, and the solenoid is designed to handle it. The rest of the contacts in the V-glide of the Club Car and on the speed control board of the E-Z-Go are only designed to withstand incremental increases in the current supplied to the motor as the accelerator is moved to the faster position. They are not designed to be the “first contact” made when the initial surge happens. Only the solenoid is “tough” enough to do that.

Typically, on all golf carts, it takes three things to happen on the low energy side of the solenoid to allow it to energize. It takes the key switch being turned on, the forward/reverse microswitch to be activated and the accelerator switch to be activated. These things prevent the cart from taking off until the driver is ready to go. In troubleshooting a cart that won’t run, the technician’s first job is to isolate the problem to either the low energy side of the solenoid or the high energy side. A good meter can be used to see if the proper voltages are where they need to be to energize the solenoid and whether the solenoid is actually working when it is energized. If the low energy circuitry is all in order and the solenoid is good, then it is time for the technician to start working his way through the high energy side to find the culprit that is keeping the cart from running.

In the next post in this series, we will take a look at a golf cart with an actual “active” motor speed controller. By this, I mean an “electronic box” that allows for speed control without the use of the big resistors. The resistors (as I mentioned in the last post) are a very effective way to control the speed of the motor, but they use bunches of energy. They simply dissipate the energy that the motor isn’t getting (when they are in the circuit) in the form of heat. The electronic controller, on the other hand, just affects the supply of voltage to the motor through a technique called Pulse Width Modulation (PWM). In the book that I reference at the bottom of this post, I spent a bunch of time explaining PWM in detail, but in the next post we will talk about it in general terms, so that it will be easy to get the idea of how it works without getting hung up in a bunch of “techy” terms. See you next time, Ron.

For information about books written by Ron Staley about both electric and gas driven golf carts and their repair, visit the following links.

Electric Golf Cart Repair, both as an eBook and in Hardcopy:

Book: Ronald L Staley: 9780578560557: Amazon.com: Books

Gas Golf Cart Repair, both as an eBook and in Hardcopy:

Gas Golf Cart Repair Book: Ron Staley: 9798987911303: Amazon.com: Books