This post is for the total beginner. Perhaps you just got an electric golf cart for the first time and are trying to get an overview of what all that stuff under the seat is. For this discussion, I am going to pretend your first cart is an older cart, not a brand new one. You probably wouldn’t be worrying about working on a new one anyway, and there are still millions of older carts out there that exchange hands. Not everyone can afford $10,000 for a new one. So, if you just bought an older cart, this might be a good starting point to get familiar with it.

When you first lift the seat on the cart, probably the first things that you will notice are the batteries. They are the energy source for the cart. They are big rectangular “boxes” and there will probably be 6 of them, however if the cart is a bit newer, there could be only 4 of them. Originally, golf cart batteries were almost always what we call 6-volt batteries. This terminology, is however, a little confusing. If you put a DC meter across a fully charged “6-volt” battery, it will read closer to 6.45 volts. By the time the battery is discharged down to 6 volts, for all practical purposes, it is totally dead. But, since the number of volts that the battery exhibits during its “cycle” (from charged to discharged), is constantly changing, we just say (for convenience) it is a 6-volt battery. Another thing about the batteries is that they are all wired in series. That means that the total voltage of the battery “pack” is 6-volts multiplied by 6, or 36 volts. Once again, this would be closer to 38.7 if they were all properly charged, but for convenience again, we’ll just refer to the pack as a 36-volt pack. The cart may also have 8-volt batteries in the pack instead of 6-volt batteries. If so, it is a 48-volt cart (6 x 8 = 48). The later carts that have only 4 batteries are 48-volt carts also, but the batteries are 12-volts (4 x 12 = 48). The 48-volt battery pack really measures about 51 volts when fully charged.

Whether you have 6, 8 or 12 volt batteries, they need to be “maintained”. The 6-volt batteries will have 3 “caps” on the top of each of them and the 8-volt batteries will have 4 of them. The 12-volt batteries will have 6 caps. Sometimes the caps are “ganged” together into one piece but when you pull off the ganged caps, you will see 3, 4, or 6 holes in the top of the battery. If you take one of these caps off, you will be looking down on the top of the “plates” of the “cells” of the batteries. There will be (or at least should be) a liquid covering the tops of the plates. The liquid (electrolyte) should only cover the tops of the cells by about a quarter to three/eighths of an inch. The space left between the top of the liquid and the bottom of the cap is intentionally left vacant for purposes of expansion. Some people think that the liquid should be all the way to the top of the battery, but that will cause all kinds of problems. For one, it disrupts the electrolyte’s ratio of sulphuric acid to water that the battery was designed to be operated with. Another thing that it will do is to cause the electrolyte to bubble over in the charging process and you’ll have a mess under the seat. The mess will cause corrosion of the battery cables, battery connectors and even the boxes that contain the batteries (not to mention what your driveway will look like). NEVER overfill the batteries.

After looking the batteries over, you can learn another interesting thing about the cart by looking at the “thing” that selects which direction the cart is supposed to move in (we call it the Forward/Reverse Switch). It will tell you whether the cart is a “series” or “shunt” type of cart. If the Forward/Reverse Switch (F/R Switch) is located on the front of the panel right behind your legs when you are driving and has a large handle on it, the cart is undoubtedly a series cart. It will take a little “effort” to move the switch back and forth as it moves mechanical parts as you shift it. If, on the other hand, it is simply an electrical switch that rocks back and forth between forward and reverse, you’ve got a shunt cart. This type of switch is generally mounted up on the dashboard. We’ll explain a little more about what all that means as we go.

When I first started working on golf carts (many years ago), almost all of the carts were series carts and that is what we will start with. So, if you found a big old clumsy handle for a Forward/Reverse switch, read on. The name series indicates that the two major components of the DC electric motor that is driving the wheels, the rotor and the stator, are wired in series with each other. The rotor is often referred to as the armature and the stator is often called the field, but they mean the same things. Both are made up of coils of wire that produce strong magnetic fields when an electrical current passes through them. These magnetic fields are controlled and manipulated in such a fashion as to get them to oppose and attract each other in a precise way so that they will cause the rotor to spin inside of the stator. We won’t get into every detail about how that happens in this article, but in other places on this (and other) websites, you could spend hours looking into it.

So, we know there has to be a motor somewhere. It is actually sort of difficult to see the motor when looking under the seat. You almost have to get your head down in the compartment and look toward the rear of the machine to see it. The motor is mounted on the piece that goes in between the rear wheels. This piece is called the “differential” or “transaxle” or even just the “rear end”, kind of depending on who is talking about it. When I first stared working on golf carts, I was surprised to learn that they had such an elaborate rear end in them. It is very similar to the rear end in a car. It distributes the power to the rear wheels so that it lets them “shift” power to the correct wheel when “cornering” just like a car does. They are filled with the same type of lubricant as an automotive rear end and of course, need to be checked for fluid level occasionally. The motor that is mounted to the differential is either a series type or shunt type of motor, depending on which type of cart it is. The motor doesn’t require any “user” maintenance. There are parts in the motor that can be replaced if something breaks or wears out, but that would have to be done by a qualified mechanic.

Now that we have a motor, we now need to supply it with a controlled amount of energy from the batteries. I say “controlled” because if we just hooked the motor directly across the battery pack the cart would take off like a flying squirrel and you wouldn’t want to be on it (or at least I wouldn’t). We want to be able to start the cart moving when we want it to, shut it off when we want to, regulate the speed of the cart to our desires, etc.

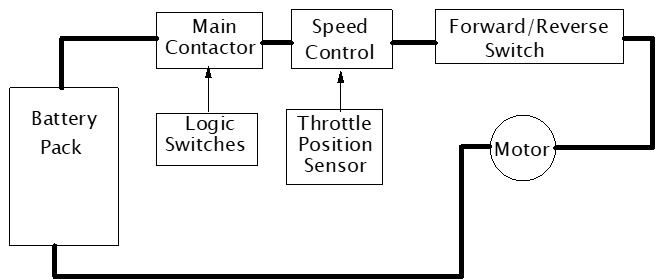

Remember now, we are using a series cart for our example. We will move on to the other type in just a bit. Here is a simplified diagram that shows our cart’s major components:

For the purposes of this post, we’ll take a look at each of these major components in a very general way and see how they fit in to the overall picture.

Back to the batteries, you will also probably notice that the wires that connect the batteries together in the series configuration are quite large. Most of the original wiring of the battery packs and motors in an older golf cart was done with 6-gauge wire. The reason the wires are so large is that when the cart is running, it takes a bunch of current from the batteries to accomplish it. If the cart has been “modified”, someone may have even put larger wires between the batteries and back to the motor, etc. The larger the wire, the less resistance it offers to the current flow and the faster the cart runs. It is quite common to find that the wire has been upgraded to 4-gauge. Whenever you see a large wire, it undoubtedly has to handle a lot of current. As a matter of fact, when I discuss golf carts, I ALWAYS think of the cart’s wiring and components as either being on the “high energy” side of things or being on the “low energy” side.

You will notice in the drawing there are both large and small lines used to connect the components. That is what that is all about. The smaller lines indicate low energy paths (low current flow) and the large lines represent high energy paths (high current flow). In general, we use low energy wires and components to control the high energy current flowing through its path and components that drive the motor.

Just above and to the right of the Battery Pack in the diagram is the Main Contactor. It is actually a solenoid. A solenoid has 2 different circuits that it is involved with. It has a coil of wire inside of it that can produce a strong magnetic field. The way that the Main Contactor works is that when a small amount of energy is applied to its “coil”, it produces a strong magnetic field which pulls a plunger down inside that shorts a pair of high energy contacts together. As a matter of fact, the Main Contactor is the only component in the golf cart that is designed to withstand “making and breaking” of the high energy current path. When the Main Contactor energizes (pulls the plunger into the contacts) it makes a distinct “clunking” sound. You will hear it each time the cart is put into motion. As you can see by the diagram, the operation of the Main Contactor” is controlled by the Logic Switches. We’ll discuss them next.

In order to have control over the operation of the golf cart, we want to establish a set of “rules” that the cart must play by when we are driving it. That’s what the Logic Switches are all about. Three Logic Switches that almost all golf carts have, are the key switch, the forward/reverse microswitch (F/R microswitch) and the accelerator switch. In other words, we don’t want the cart to move until we have turned on the key switch, told the cart which direction to go, and have stepped on the “gas”.

The key switch is physically very similar to an automotive type key switch (without the start position). It is usually mounted on the dashboard of the cart. The F/R microswitch is a little less obvious, but it is attached to the larger F/R switch (the one we found earlier) that is in the high energy circuitry. The F/R microswitch is manipulated by the mechanical “shifting” of the F/R high energy switch and is used to indicate to the speed control system which direction has been selected. The accelerator switch is likewise connected to the accelerator in such a fashion as to let it detect when the driver is ready to go. It takes all three of the Logic Switches to be “happy” before we can operate the cart. The three logic switches are intentionally wired in series with each other, so “opening up” any one of them, should break the circuit and stop the cart.

The next box to the right of the Main Contactor (in the diagram) represents the Speed Control System. If you have a really old cart, the speed control system may consist of big coils of wire that are actually resistors that are switched in and out of the motor’s circuitry to speed up or slow down the cart (the less resistance in the path allows for the motor to run faster and more resistance slows it down). These resistors were usually mounted just behind the battery pack. So, if you lift the seat up and look back there and you see some big coils of wire, that’s the system you have. On the later model series carts, the speed control is accomplished by an electronic controller. Instead of adding and subtracting resistors, this type controls the energy to the motor by applying “pulses” of energy to the motor in proportion to the need of the operator. The process that the controller uses is called pulse width modulation (PWM) and we could spend hours discussing it, but for the purposes of this post, it’s not necessary. As you look beneath the seat of the cart, locating the electronic speed controller can be tricky. Through the years, the manufacturers of golf carts have stuck motor speed controllers in every conceivable location in the cart. The is usually a box, only about 6 inches or so by 10 inches of so. I’ve seen models where the controller cannot be seen from the battery box area at all. If it is in the battery box area, it will probably be covered up (to protect it from water and dust). The controller will of course have both large wires and small wires connected it. The larger wires are part of the high energy circuits (to drive the motor with) and the low energy (logic) circuits that I have talked about. The motor speed controllers are not intended to be repaired, at least not by a traditional shop, and generally need to be replaced. They are, of course, a very expensive part of the cart. They may go for as much as $1000. So, if you do locate it, don’t mess with it!

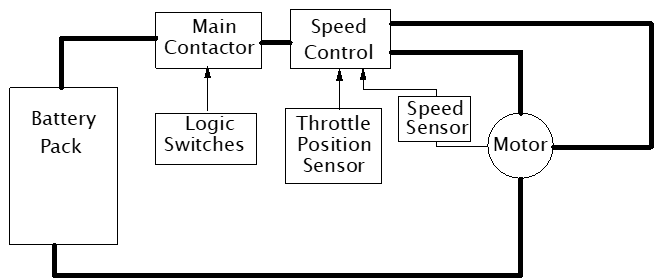

We talked (just a little) about there being two different kinds of carts: series and shunt. This is where we’ll discuss the shunt type. Instead of having a series circuit where the same current passes through the stator and rotor of the motor, the shunt cart has a “separately excited” stator. This type of controller is therefore often referred to as a “sepex” (short for separately excited) controller. Therefore, the shunt cart uses a different type of speed controller than the series cart does. The controller, has a separate output for the stator and is more sophisticated in how it supplies the energy of the batteries to the motor. As mentioned before, this is the type of cart that will have a simple electrical switch for F/R switch instead of the old mechanical switch used in the series cart. So, if your cart has an electrical F/R switch, this is the type of cart you have. This type of system (shunt) also provides what is called “regenerative braking”. That means that when you let off of the accelerator, you will feel the cart start to “hold itself back” like you were stepping slightly on the brake pedal. It actually adds some of the energy that is produced by the motor while it is “braking” back to the battery pack. The shunt type controller usually has more programming options available than the series controller does. So, the acceleration, breaking, top speed, etc. can be adjusted in a more efficient manner. The shunt system usually includes a sensor mounted on the end of the motor that monitors the speed of the rotor’s rotation also. So, our diagram changes just a little bit:

No matter which type of cart you have (series or shunt), the speed controller is what rations the energy to the motor. In order to do so, it has to know what the position of the throttle is, so that is the reason for the box just below it (Throttle Position sensor). Several different types of Throttle Position Sensors have been used to do the job. The most common types are potentiometers and inductive types. They are mounted in such a way that they alter a voltage that is supplied to the controller as the throttle is moved (accelerator is stepped on).

Another important part of a golf cart is the brake system. The brake system on most golf carts are mechanical (not hydraulic, like on your car). They employ cables to operate the brakes and usually are only placed on the rear wheels. They are usually “shoe” type breaks, not “disk” type. Now, there are exceptions to all of this, but I’m talking about the majority of the older carts here. Another feature of the braking system is that it usually includes a 2-piece brake pedal. If you push on the larger portion of the pedal, it applies the brakes in the normal fashion. But, if you push on the smaller part at the top of the pedal, you apply a ”hill” or “parking” brake. It is intended to “catch” hold and to remain engaged until the bottom part of the pedal or the accelerator is pushed again to release it.

There is a new battery technology that is slowly taking over in the golf cart business. The traditional lead-acid batteries that we have been using for years are being replaced by lithium-ion batteries. The new batteries are MUCH lighter and deliver more power than the old lead-acid type. It is even fairly common to see an older cart that has been converted over to the new type of battery. They, of course require a special charger. If you just bought a used cart, it might even be one that was converted.

Probably the next step in the evolution of electric carts will be that of going to an AC motor. That takes quite a re-design because the source of energy for the batteries is still DC. So, the DC must first be changed into AC (a process called inversion). In addition to that, an AC motors speed is controlled by varying the frequency of the AC supplied to it. The AC motors are also 3-pole, so now, the controller needs to be not only a DC to AC inverter, but also a 3-phase frequency regulator. Now THAT’S a controller! There are models with AC motors currently on the market and there are even some conversion packages available to turn one of the old DC carts into an AC cart (get you checkbook out, they are quite expensive).

In this post I have tried just to point out to the beginner some of the equipment he is sitting on when he is “carting” down the road or on the golf course. There is lots more information about carts and how they work in this website, so feel free to look around, Ron.

For information about books written by Ron Staley about both electric and gas driven golf carts and their repair, visit the following links.

Electric Golf Cart Repair, both as an eBook and in Hardcopy:

Book: Ronald L Staley: 9780578560557: Amazon.com: Books

Gas Golf Cart Repair, both as an eBook and in Hardcopy:Gas Golf Cart Repair Book: Ron Staley: 9798987911303: Amazon.com: Books