In the last post, we discussed carts with the most sophisticated “series” speed control systems. The controllers contained microprocessors and were capable of being “programmed” to fit the needs of the cart and its driver. What do we mean by “series”? There are two major components within a DC motor that make things work. They are the “stator” and the “rotor”. They both consist of many coils of wire, which when energized by allowing an electrical current flow through them, create very strong magnetic fields. They two forces are placed in opposition to each other (within the motor) in such a fashion as to cause the rotor (also referred to as the armature) to spin inside of the case of the motor where the stator (also referred to as the field) is attached. The energy provided to the rotor is supplied through a part of it called the commutator. The “brushes” provide the physical contact of the circuit to the armature. The brushes “rub” on the commutator as the armature spins, thereby providing a continuous supply of energy to the armature.

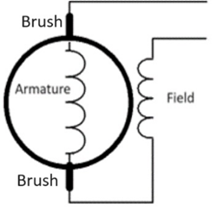

The following diagram would represent how the armature and the field coils are connected in a series relationship:

The wires at the top righthand corner then go off to the speed controller, forward/reversing system, solenoid, etc.

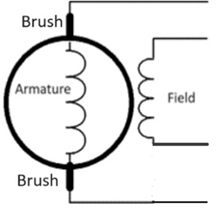

In the next diagram, both the armature and the field connectors go back to the speed controller as individual pairs. The controller then supplies the reversing and also operates the solenoid.

With the shunt system, the current that flows through the field coil can be manipulated, no matter what is going on with the rotor (armature) circuitry. This offers a lot more flexibility in the design of the speed controller. So, even if the voltage to the armature is lowered by an increased load, (like going up a hill) the current flow through the field can be independently maintained or enhanced by the controller. The process of altering the current flow through the field coil for different diving conditions and to match other unique requirements of the cart’s hardware (motor, tire size, required torque and speed) is referred to a “field mapping”. The manufacturer can allow more sophisticated options to improve and customize the cart’s performance.

In general, here are some of the advantages of a shunt motor and speed control system:

In addition to the field and armature connections, a shunt motor has a cable connected to the end of the motor that goes to a speed sensor, so the controller “knows” how fast the motor is spinning at all times. This is very helpful information that can be used to ensure the correct performance of the cart.

Shunt motors can provide more torque at “take off” due to the fact that the current flowing through the field winding is not limited to that of the armature (it is supplied separately from the controller).

The shunt motor can be used to produce “motor braking”. That means that when you go down a hill, for example, the cart will try to hold itself back to the desired speed, without the driver needing to step on the brake pedal. The amount of motor breaking is programmed as one of the options of the controller.

A given speed can be maintained over a wider range of “load” conditions (up and down hill). This, again, is due to the fact that current flowing through the field is not limited to what is happening with the voltage supplied to the armature.

Of course, some manufacturers make some of the options that affect the performance of the controller “non-adjustable” by the cart’s owner. This requires the customer to return the cart to the dealership to make the adjustments (for hefty fee, of course). As a technician trying to provide service to customer’s carts, this is very aggravating. You have a customer call up and would like to get a little more speed out of their cart, and all you can do is refer them to an authorized dealer. Thank goodness, some of the controller manufacturers have come up with replacement controllers that WILL allow the customer or his local technician to affect all of the available options. Some of these controllers can even be programmed through the use of “Blue Tooth” technology so that the options can be reset right from a smart phone. On these models, you don’t even have to make a “serial” or USB connection to the controller to make adjustments. You just “pair” the controller to the phone through an application that is downloaded to the phone over the internet and away you go. And just when you think it can’t get any better, some smart aleck came up with an even more efficient system than even the sepex controller system. It involves converting the battery’s energy into an alternating current (AC) source and using an AC motor to power the cart. Wow, what will they come up with next? We’ll discuss the AC version of an electric golf cart’s system in the next post. Till then, keep on “cart’in, Ron.