This post is the first of several on the subject of the evolution of electric golf carts.

According to Wikipedia, it was in the early 1930’s when it all began. A guy named JK Wadely noticed the convenience offered by a three-wheel electric cart that had actually been designed for helping somebody disabled get around a grocery store (and other non-golf related places). He decided to try it out on a golf course and found it rather UNSUITABLE for such terrain, but decided things could be “adjusted” to make something “kind of like it” that would work very well for the purpose. The idea caught on, but it wasn’t until the 1950’s that Merle Williams began production of the Marketeer electric golf cart in Long Beach, California. Through the years, many other manufacturers jumped in and started producing electric golf carts also.

The early carts all had some things in common, like using batteries, and DC motors, but they came up with several variations of how to control the speed of the vehicle. The batteries were usually lead acid batteries, just like the industry has used for years and years. They are quickly being phased out by the later technology of lithium-ion batteries, but the lead acid batteries have truly been the standard for the golf cart industry for many years. In order to understand speed control, we need to take a look at how DC motors work.

The common method of using a DC motor in a golf cart for many years was called a “series” wiring configuration. The rotation of the shaft of the motor depends on magnetic fields opposing each other within the motor, between the field coil (attached to the housing of the motor) and the armature coil (attached to the rotating shaft). These magnetic fields are the result of the cart’s batteries being wired in such a fashion that current can flow through both of these coils in a single circuit. The more current that flows through the coils, the stronger the opposition is that occurs between these coils and, therefore the speed of the shaft is increased. In order to control the speed of the motor, we need to be able to control the amount of current that is available to the series wired coils. As a matter of fact, for many years, the main difference between models of golf carts was primarily in how they controlled that amount of current.

I don’t want to get too “mathy” in this post but it is important to know that the amount of power (in watts) that a motor can produce is limited to the strength of the source supplied to it (in volts) multiplied by the amount of current (in amps) that is available. In other words, Power (in watts) is equal to volts supplied (E) times the current (I) that is available or P = I x E. So, in order to reduce the power that the motor produces, we have to control either the E (voltage) to it or the amount of current (I) that is available.

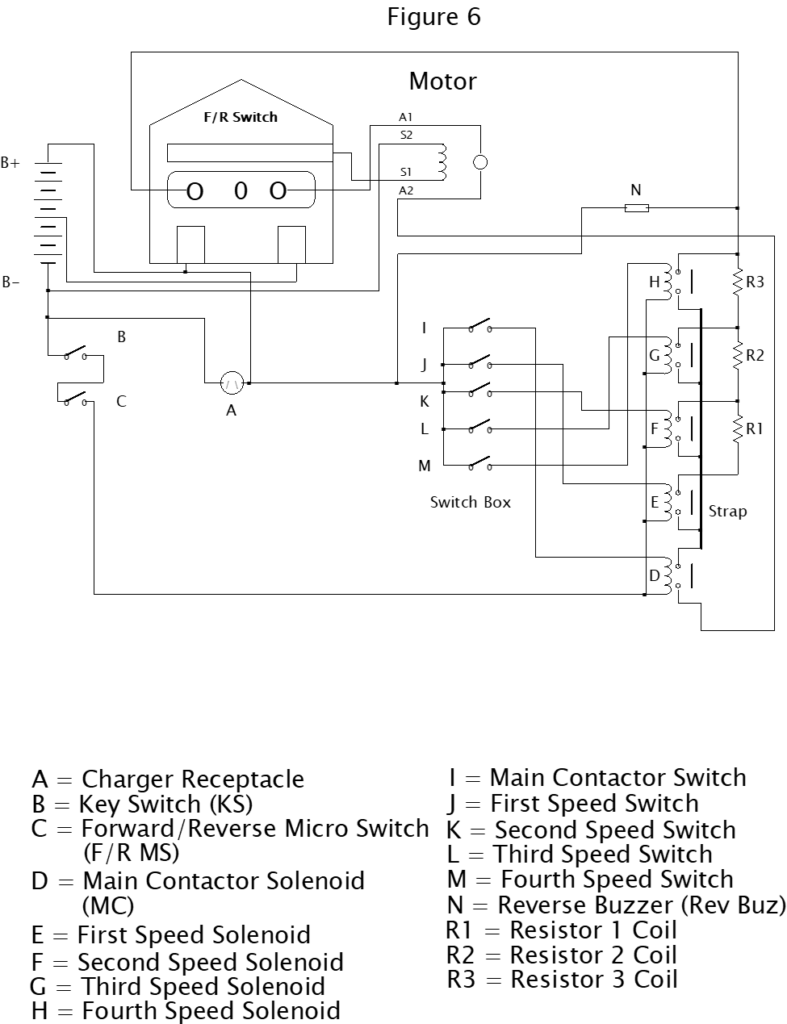

One of the ways that was used in some of the early carts was that of switching more or less batteries into the source to the motor. In most carts, there were a total of six (six volt) batteries wired in a series configuration to achieve a maximum potential of thirty-six volts that could be connected to the motor at one time. But you could use heavy duty switches or solenoids to remove some of the batteries from the motor’s supply to slow the motor down and switch them back into the circuit to speed things back up again. The technique came, however, with its problems. After driving the cart a reasonable distance, you had a battery pack with batteries that were unevenly discharged. Depending on what speed the cart had been driven at most of the ride, some batteries would be used more than others, resulting in an unevenly discharged pack. The charger wasn’t smart enough (or designed) to know which ones to give extra charge back to in the charging process, so the battery pack was constantly unevenly charged. This resulted in a much shorter life expectancy for the pack. In all the years that I worked on carts, I only ran across a couple with this type of speed control system, so I won’t bother you with a wiring diagram of one. Instead, we’ll turn to the next method of reducing the voltage and the current to the motor that was quite common for many years. It was accomplished by adding a variable amount of resistance in series with the motor. In order to discuss the system, I have copied one of the drawings from a book I wrote about golf cart repair. The drawing shows a typical method of how the resistance was added and removed. This diagram is of an early Club Car cart that used what was referred to as a resistor system:

For the purposes of this post, we won’t go into a detailed description of exactly how it all works, but the point is that when the accelerator is advanced (once the key switch and the F/R microswitch are activated), the resistors are placed in series with the motor to keep its seed down. The maximum current through any circuit is equal to the voltage applied to the circuit divided by the resistance offered by the circuit (I = E / R). So, as there is more and more resistance added to the circuit, the current through the motor is decreased (thereby slowing its rotation down). When the accelerator, that is linked to a series of switches, is moved it activates switches, that in turn, control solenoids to remove resistors from the motor’s circuitry. The resistors (if you ever look under the seat of one of these carts) are big coils of wire that not only provide resistance of the circuitry, but are large enough physically to be able to dissipate the heat that is produced in the process. The main disadvantage of this type of system is that in the process of slowing the motor’s rotation, much energy is consumed (dissipated as heat) by the resistors. That limits the range of the battery pack. Of course, all that energy must be replenished in the batteries’ charging process. Another problem is that with five solenoids at work, there is definitely room for much more failure due to wear and tear on them. Golf cart solenoids ae a special “breed’ of solenoid. They are what is called a “constant use” solenoid. Unlike an automotive solenoid, which is only used in the starter circuit long enough to get the engine started and then is disconnected, these solenoids must withstand being used in their circuitry for long periods of time. For a detailed discussion of the operation of this type of system, I recommend the book I wrote called Electric Golf Cart Repair 101 (and a half). The link at the bottom of this post will get you more information about the book.

In our next post in this sequence, we will look at a couple of models (one Club Car and one E-Z-Go model) that still used resistors but worked with only one solenoid (less maintenance). The basic operation is still the same, but the switching “in and out” of the resistors is simplified and made a whole bunch more reliable. See you next time, Ron.

For information about books written by Ron Staley about both electric and gas driven golf carts and their repair, visit the following links.

Electric Golf Cart Repair, both as an eBook and in Hardcopy:

Book: Ronald L Staley: 9780578560557: Amazon.com: Books

Gas Golf Cart Repair, both as an eBook and in Hardcopy:Gas Golf Cart Repair Book: Ron Staley: 9798987911303: Amazon.com: Books