I am often asked about the function of the Fuel Filters used in gas golf carts. I also get asked a lot about how much fuel should be seen in the Fuel Filter(s) as the system operates. So here is a description, as I understand it.

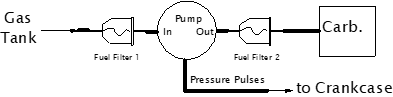

There really should be two Fuel Filters in the system as indicated by the above diagram. Fuel Filter 1 is where it is, for the obvious reason of keeping anything of “size” that is “living” in the gas tank from making its way to the Fuel Pump. Fuel Filter 2 is to catch anything that gets by the first filter and anything that might get loose in the Fuel Pump (like small pieces of gasket material, dried gas or whatever) and keep it from getting into the carburetor. As people fill the Gas Tank with fuel, they can’t help but eventually get some “dirt” in the tank. Funnels are often used that haven’t been cleaned very well and gas cans also collect “debris” through the years. The filters DO NOT keep water from going through the system. They only keep “particle” stuff out. The ability of a filter to hold stuff back (not let it through their filtering material) is dependent on the “pore” size of the material used to do the filtering. Most golf cart Fuel Filters have a filter rating of about 30 microns. That means that they can hold back anything that is as large as or larger than 30 microns (30 x 10 to the minus 6th power). For reference, a human hair is about 70 microns. A molecule of water is only about 275 picometers in size (275×10 to the minus 12th power), so, the pore size of the filter is WAY to large to hold a water molecule back. Filters also have an “efficiency” rating, meaning that they are not 100% efficient. They can’t guarantee that every “pore” is exactly the same size, so there is a little room for something larger than 30 microns getting through occasionally. You will be hard-pressed to find any documentation on a specific filter, but they aren’t perfect, so 2 is better than 1.

As indicated above, the flow of the fuel starts with fuel from the Gas Tank being sucked into Fuel Filter 1. The reason that there is a suction to make it flow, is due to the operation of the Fuel Pump. There is a detailed description of just how and why the Fuel Pump sucks fuel in one side, and pushes it out the other side at this link Chapter 9-Gas – fuel pumps – Welcome to Golf Cart Stuff Hodgepodge. For purposes of this discussion, we’ll just assume that it is working properly. We must be aware, however, that the Pump is only capable of pushing the fuel out of its output port with a pressure of about 1.5 to 3 pounds per square inch. There is a good reason for this. If it were able to achieve higher pressures, it could “force” fuel into the carburetor even when it wasn’t needed. The needle and seat valve in the carburetor closes when the amount of fuel in the float bowl is correct. The carburetor’s job is to mix the right amount of fuel and air together to maintain about a 14.7 to 1 mixture going into the engine (14.7 parts of air (by weight), to 1 part of fuel). If the needle and seat valve couldn’t close, the fuel would just keep flowing in and overfill the bowl. If you ever work on a cart that has a defective needle and seat valve that won’t close correctly, you will see the engine running way to “rich” or even flooding out altogether. Lots of times, the valve isn’t defective at all, but just has some particle stuck in it that is holding it slightly open. There is a “vent “at the top of the carburetor to allow air to escape the bowl as fuel rushes in, and often when the needle and seat won’t close, you will even see fuel running out of the vent (usually through a small hose to the ground).

So, as the needle and seat valve opens, the Fuel Pump begins to push fuel into the float bowl. At this point, if you have transparent Fuel Filters, you can observe the fuel flow in both Fuel Filters 1 and 2. It is important to note here that the filters won’t “fill” up. As Fuel Filter 1 starts to try to fill, the fuel from it is quickly passed on to Fuel Filter 2 and on to the carburetor. When the Float Bowl is full (as the needle and seat closes), the flow will stop, because there is nowhere for the fuel to go anymore, unless there is a leak in the system somewhere. So, at that point, the filters have fuel left in them that isn’t going anywhere, but they are by no means full. How full they are, depends on what exactly was happening when the needle and seat closed. The fuel is working its way through the system to the carburetor in pulses (squirts) that are controlled by the up and down movement of the piston in the crankcase. The important thing to look for is that there are signs of “wetness” in both of them. They should never be “dry”. When you look at them, it varies as to what you might see at any particular time (what part of the pulse cycle was the Pump in when the valve closed). Another major factor in what you will see is the “orientation” of the filter itself. If a filter is mounted perfectly horizontal, its input port and output port are in line with each other horizontally, so as soon as the level of the fluid in the chamber gets to about half full, the flow of fuel will begin. If the filter is aimed “up-hill”, then the level will have to get higher. If the filter is mounted “vertically”, it all changes again. Then, depending on which port is higher than the other one, you may see almost no fluid (output is lower than input) or you may see the filter almost full (input is lower than output).

I always put 2 new transparent Fuel Filters in the system (Fuel Filter 1 and Fuel Filter 2) as indicated by the diagram. If I have to do any troubleshooting of the system later, looking at the filters can be quite useful. For instance, if I look down and see either Fuel Pump or both are dry, I would go immediately and disconnect the fuel line going to the carburetor, spin the engine over, and see if any fuel starts to flow through the system. If not, I would go to the Fuel Pump and start looking around. It is fairly common for the line running to the engine block (pulse line) to get old and develop cracks or even to become “smashed” and shut the whole system down. The best way to troubleshoot Fuel Pump issues is with a vacuum/ pressure gauge. I would start by disconnecting the line from the Fuel Pump that goes to the engine and connecting the line I just removed to the gauge. When I spin the engine over, I’ll see the gauge go “wildly” back and forth between vacuum and pressure as the piston goes up and down. Then I would reconnect it (if everything seems fine) and the disconnect the line from the Fuel Pump that goes to the Gas Tank. Then I would connect the gauge to the input port of the Fuel Pump. While spinning the engine over, the gauge should be “drawn” down into the vacuum area of the gauge’s scale. If that doesn’t happen, the “pick up” hose in the Gas Tank could very well be clogged. If it is ok, I would then move to the line that goes to Fuel Filter 2, remove it, and place the gauge on the output of the Pump. As I spin the engine over, the gauge should go up (it takes a little while) to about 1.5 to 3 psi. If you don’t have a gauge, lots of people just use the “redneck” approach, and hold their finger over the ends of the hoses instead of the gauge. The pressure is subtle, but both pressure and vacuum can be detected with that “old fashioned” approach.

So, there you have it. Between this article and the one referenced earlier, you should know everything I know about the subject of Fuel Pumps.

Ron Staley has published the following books, and you can get more information about them by just clicking on each title below:

Electric Golf Cart Repair 101 (and a half)

Techniques, Tips, Tools and Tales

Gas Golf Cart Repair 101 (and a half)

Techniques, Tips, Tools and Tales

4-Stroke Golf Cart Engines Explored

What Makes Them Tick

By an old Slot Machine Mechanic