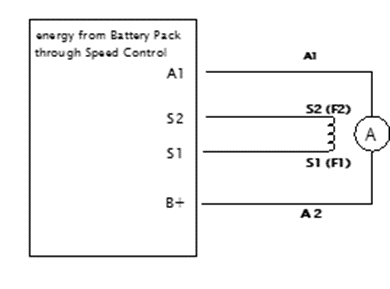

Electric golf cart motors have evolved through the years so, I’d like to talk about the various types in use. For years, the standard golf cart motor was the “old reliable” series wound DC motor. The motor consists of two major pieces. One is called the stator or lots of times referred to as the field. In the case of the series motor, it is made up of windings of wire, which when supplied with an electrical current form strong magnetic fields. In the case of golf carts, if you opened the motor up and took a look at it, you would find that the stator is attached to the case of the motor and surrounds the other major piece of the motor called the rotor or armature. The rotor is also made up of windings that produce strong magnetic fields. The rotor’s magnetic fields are intentionally set up to oppose and be attracted to the magnetic fields of the stator in such a fashion as to make the armature rotate when the electrical current is applied to both the stator and the rotor. As the name might suggest, the electrical connection to the stator and rotor form a series circuit. So, all of the current that is supplied by the battery pack of the cart flows through both the stator and the rotor. The electrical connection to the rotor (which moves) is made through a set of “brushes” that ride on a part of the rotor that is called the commentator. The commentator is responsible for reversing the phase of the magnetic fields as the armature rotates. The process is often referred to as a commutation. Electronically, the series system could be represented by something like the following:

The rotor’s connections to the outside world are usually referred to as A1 and A2 (for Armature) and the stator’s are usually referred to as F1 and F2 (for Field) or S1 and S2 (for Stator).

Speed control for the series configuration is either done by mechanically adding resistors in series with the motor to slow it down and then removing them to speed it up, or with a controller (more modern approach) that provides pulse width modulation to increase and reduce the voltage and therefore the current through the series circuit.

The series golf cart configuration has been around for a long time and is very reliable and quite serviceable. Because the electrical contact to the rotor is made through brushes which eventually “wear” out, the motor does require some periodic maintenance. In addition to the brushes, the commentator can develop “pits” and “wear marks” where they make connection with the brushes that have to be corrected by “turning” and “polishing” the commentator on a metal lathe. There is also a bearing that needs to be replaced periodically. It is on the commentator end of the motor’s shaft. On this type of motor setup, the motor does not have a thrust bearing in it. The output shaft of the motor couples into the input shaft of the differential. The input shaft has a bearing mounted right in the case of the differential, and that acts as the thrust bearing. In order to service the motor, you really need a metal lathe (to turn and polish the commentator), a bearing puller to remove the commentator bearing and a press to replace the bearing with. However, the series motors require this kind of maintenance very infrequently.

The next type of motor to come on the scene for golf carts still consists of a wire wound stator and rotor, but they are not wired in series. Instead, the stator (field) is “separately excited”. That means it gets its energy supplied in what is sometimes referred to as a “shunt” configuration. Electronically, it would look something like this:

Granted, all of the energy still comes from the battery (ultimately), but it comes to the rotor and stator from two different outputs of the controller (resistors aren’t used with this type of system). This enables the controller to manipulate voltages and currents in a much more sophisticated way. The way that the stator is controlled is referred to as the controller’s “field mapping” whereas the rotor is still pulse width modulated much the same as in the series carts. This configuration allows all kinds of options in its programming, including new features like “regenerative braking”, electronic switching of the Forward and Reverse travel of the cart, more sophisticated speed control, etc. There is usually a sensor on the sepex type motor that reports the speed of the motor’s rotation back to the controller.

The separately excited field has earned this system several names including “sepex” (short for separately excited field) or “shunt” system. The shunt refers to fact that the rotor and stator coils are wired in somewhat of a parallel style (as opposed to series).

Another popular kind of a DC motor, now of days, is one in which the there is an electromagnetic stator but the rotor uses permanent magnets. With the permanent magnets in the rotor, there is no need for brushes (a big plus). The current reversal (commutation) that used to take place with the commutator is done by affecting current flow through the electromagnets (stator) with a special controller. I won’t go much farther into that type of motor in this post, because I have never heard of one being used in a golf cart.

The newest type of motor system to come to the golf cart industry is the AC system. AC motors have several advantages over DC motors including the lack of needing brushes to operate. There are lots of opinions out there about which motor (DC or AC) is more efficient, but it really does depend on what aspect of the motors’ operation you are looking at. It has been estimated that in the overall sense of operation as a golf cart that the AC system can be as much as 39% more efficient.

AC motors don’t require “commutation” like DC motors do, because the direction of the magnetic fields are constantly being reversed by the alternating current. That makes building the AC motor much easier. However, AC single phase motors (like those used in refrigerators or air conditioners, etc.) do require a method to throw the magnetic fields in the stator and rotor out of phase in order to get the motor started. That usually involves “start windings” with relays or “start capacitors”. However, golf carts use three phase energy to drive the motor, so that isn’t an issue.

There are some obstacles to be overcome though. One is that the batteries in the golf cart are DC, NOT AC. We must turn our DC source into an AC to accommodate the three phase AC motor. That is accomplished by the use of an inverter that is part of the controller. It operates much like an inverter that you would use to run an AC appliance (like a drill or a blender or any other small appliance) from a car’s battery. The golf cart’s inverter not only turns the DC source into AC, but also provides three phases. Now, I think that is a pretty sophisticated inverter.

There is another major difference between the DC system and the AC system. That is when it comes to speed control. With a DC motor, you can speed it up or slow it down by adjusting the voltage to the motor. As I mentioned above, whether it is done with resistors or with pulse width modulation in a controller, it is fairly simple to do. An AC motor’s speed must be regulated by changing the frequency of the AC current. They call the process “variable frequency regulation” (often referred to as variable frequency drive or VFD). So, our controller just got even more sophisticated. It is now a variable frequency regulator as well as a three-phase inverter. WOW!

There are kits that are available to convert a conventional DC series or sepex system into an AC system. The kits include an AC motor, the inverter/controller, and all the necessary wiring and accessories needed to do the conversion. I didn’t say they were cheap, but they are available (usually around $2000). The manufacturers of the kits make the following claims:

Increase top speed (up to 35 MPH)

Increased torque

Increased battery efficiency (longer run times)

Better regenerative breaking than a sepex (shunt) system This has been a rather quick tour of the types of motors used in most golf carts. I could spend hours on each of the types, but I hope this provides an “overview”. Ron.

For information about books written by Ron Staley about both electric and gas driven golf carts and their repair, visit the following links.

Electric Golf Cart Repair, both as an eBook and in Hardcopy:

Book: Ronald L Staley: 9780578560557: Amazon.com: Books

Gas Golf Cart Repair, both as an eBook and in Hardcopy:Gas Golf Cart Repair Book: Ron Staley: 9798987911303: Amazon.com: Books