Probably the first step in troubleshooting most electric golf cart problems, is to see what is going on with the batteries. Let’s say I am working on a 36 volt cart. The first thing I do is measure the overall battery pack voltage, with the cart just sitting idle. By overall, I mean from the lowest point in the battery pack to the highest. These points are referred to as B- (lowest) and B+ (highest). Sometimes it might be just a little confusing trying to determine just where these points are located but here are some tips on doing it:

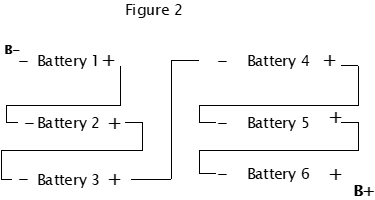

These points must eventually end up being connected to the cart’s charger receptacle (where the charger plugs in). The batteries in the cart are wired in a series connection, so the general set up looks something like this:

Never mind the “Figure 2” reference. I cut and pasted the drawing from a book I wrote about electric golf carts that covers battery information in depth. The book is called Electric Golf Cart Repair 101 (and a half). There is a link to get more information about the book at the top of the site in the menu section.

The drawing is correct from an electronic stand point, but it doesn’t give you any idea of how or where the batteries will be physically located in the cart. There may be two facing one direction and four facing another direction, or whatever. The manufacturers put them in whatever way they can to accommodate the size and shape of the “under the seat” compartment. It really doesn’t matter, however, as long the series connection is as the drawing indicates, with minuses to pluses, in a chain. You will notice that when you look under the seat, there will be five heavy wires that provide the series connections between the batteries. On most standard carts, the wire is 6 gauge, which is about 3/8 of an inch in diameter. Many people, in an effort to reduce resistance to current flow through the circuit, and therefore improve the performance of the cart, will “upgrade” to even larger wire. Some go to 4 gauge wire or even in some cases, you might find 2 gauge wire. Going with the bigger wire really does help the carts performance, especially when the cart is equipped with a high speed or high torque motor (or both). These upgrade motors draw more current than the stock ones and really push the limits of the 6 gauge wiring. The high-performance motors usually come in a “package deal” that includes an upgraded motor speed controller that is capable of handling the additional current and the bigger wires just makes good sense to complete the upgrade.

So, the interconnecting wires between the batteries will be relatively short pieces of this heavy wire. At the ends of the series string, you will have the same size wires going off somewhere else (at B+ and B-), but that will be the only two places where the batteries aren’t connected to another battery. These two places will usually also have some lighter wire (probably 10 gauge or so), running over to the charger receptacle. There are some exceptions. For instance, in the case of the 48 volt Club Car, the B- terminal doesn’t go to the charger receptacle directly, but through a device called an On Board Computer, which in turn connects to the charger receptacle, after certain criteria have been met. But even in that case, if you start by finding B+ (the only wire on a positive terminal of a battery that doesn’t go to another battery) and trace back through the chain going from minuses to pluses and so on, it will be easy to determine when you get to B-.

At this point, in order to get good information, we need start by charging the batteries. They need to be put through an entire “charge cycle”, meaning that a known good automatic charger has been connected to the pack and allowed to charge them until the charger has shut itself off. Thank goodness for automatic chargers. In the old days when all a charger had was a manually set timer, we had to just take SWAG (scientific wild a** guess) at how long to set the timer for. The result was that quite often the batteries never got completely charged or got overcharged to the point that they boiled out part of the electrolyte in them.

So, once you have located B+ an B-, the next thing that you want to do, is to connect a voltmeter to these to points. Obviously, the positive probe (usually red in color) goes to B+, and the negative probe (usually black in color) will go to B-. At this point we are just “sniffing around” to get a general idea about the condition of the batteries. If the batteries have just gone through a complete charge cycle, a 36 volt battery pack should read about 37.9 volts (after letting them sit for at least 30 minutes after being removed from the charger). If they haven’t been charged for a while, they will read somewhat lower, but the important thing at this point is to see if there are any substantial DIFFERENCES between the batteries. To check for that, you need to go from battery to battery and test between the – and the + terminals of each battery individually. Each of the charged batteries should read about 6.31 volts (37.9 divided by 6). If you find one that is significantly lower than that, you may have just found the source of your problem with the cart.

The next step is to check the overall voltage of the battery pack and each individual batteries voltage under a load. There are some fairly decent “load testers” on the market, but since they don’t load the batteries exactly the same as the running golf cart does, I prefer using the cart to do the testing, if at all possible. Obviously, if the cart won’t run at all and you have verified the 37.9 volts, then your problem probably isn’t with the batteries, but at least you have gotten them out of the picture for now, and you can go on troubleshooting other components. Checking the batteries should certainly be the first step. If the cart WILL run but has performance problems, by all means go on to this load test part of the procedure. Batteries can test fine but “drop out” under a load. Typical symptoms would be “chugging”, “lack of power” or even “cart slowing way down on hills”. And yes, I’ve had batteries develop INTERMITTANT issues, where the cart runs fine part of the time, but not all of the time.

In order to do the load testing with the cart, you need to devise a method of keeping the probes of the meter connected to the battery terminals while watching the meter as you are putting the cart through its paces. I use two small jumpers that have alligator clips on their ends to facilitate that. I connect one end of each jumper to each of the probes and the other ends of the jumpers to the “points of interest”. In order to be able to see the meter while I’m driving the cart, once the probes have been connected to the test points, I place the meter on the floor of the cart and, making sure that the leads don’t get pinched when I let the seat back down and I’m ready to start testing. I have found that I can usually use a small block of wood wedged between the seat and the body that it sits on to keep the seat from closing tight enough to pinch the wires of the meter.

The first test, like before, is to connect the probes (with the jumpers) to B+ and B-, but this time read the meter while driving the cart. With a healthy battery pack, as the cart starts to move, the meter will drop down a little, but not very much, and as the cart starts to get up to speed (proportional to the position of the accelerator), the meter should “crawl” back up toward the 37.9 volts that it started out at. When you really put the “pedal to the metal”, the meter might even jump down as low as 35.5 volts or even a little less, but only for a second or two. The meter will then start climbing back up toward its 37.9 reading as the cart picks up speed. If that is the way it acts, you probably don’t have any battery problems and really don’t need to continue with the battery testing. Your problem with the cart is likely something else.

However, let’s say that when you step down on the accelerator, the meter drops to something much lower than 35.5. Now it’s time for the rest of the test. That means connecting the probes to each individual battery, one at a time, and repeating the driving part of the test. As mentioned before, if the battery pack is charged to 37.9 volts, then each battery should be contributing 6.31 volts to the total. If the battery pack, under the pedal to the metal test drops to the 35.5 that we talked about, then that means that the lowest that you should read across any individual battery would be 5.9 volts (35.5 divided by 6).

You might find that they ALL drop down way below 5.9. If so, it’s probably time for all batteries to be replaced. You might find that only one of the batteries is “dropping out” (as we call it). If so, you can just replace that one. However, if all of the batteries are the same age, and one or two are dropping out, it’s probably just a matter of time before the rest of them start giving you problems also. So, if you can afford it, it might be a lot easier and save a bunch of time in the long run, just to go ahead “bite the bullet” and replace them all, right now.

How long a set of batteries should last, is a good question, and one that I hear all the time. My standard answer, is about 4 years. Lots of things can affect that, but if they are properly cared for it seems to be a good answer. Where I live here in South-Central Florida, lots of people are only here during the winter months, and let the cart sit the rest of the year, unattended. That can reduce the life expectancy considerably. The most important thing is that you keep the electrolyte level where it should be. If you take one of the lids off of the top of a battery, you will see the ends of some plates sticking up. The electrolyte (the liquid) should always be kept at a level of about a quarter of an inch above the tops of the plates. If the plates are exposed to air, a process call sulfation occurs and is detrimental to the efficiency of their operation. The next most important thing is that the batteries are “cycled” at least once in a while. That means that they should be discharged at least slightly and re-charged as often as possible. Of course, that all gets thrown out the window when you wrap the cart up and let sit for 6 months. It is best to find someone who will at least check and maintain the electrolyte level occasionally, and it is even better if you can get that someone to drive the cart once in awhile and re-charge it also. That can’t always be arranged, so you just have to do the best that you can, but expect that the batteries aren’t going to last as long as they would under normal circumstances.

So, I strongly recommend that as you start trying to resolve almost any problem with an electric golf cart, the batteries are a good place to begin. I can’t begin to tell you how many times people brought me carts to repair and the problems ended up being a bad battery (or all of them). In lots of cases, the people had even replaced other parts (to no avail), when properly testing the batteries would have saved them lots of time and money.

Ron Staley has published the following books, and you can get more information about them by just clicking on each title below:

Electric Golf Cart Repair 101 (and a half)

Techniques, Tips, Tools and Tales

Gas Golf Cart Repair 101 (and a half)

Techniques, Tips, Tools and Tales

4-Stroke Golf Cart Engines Explored

What Makes Them Tick

By an old Slot Machine Mechanic