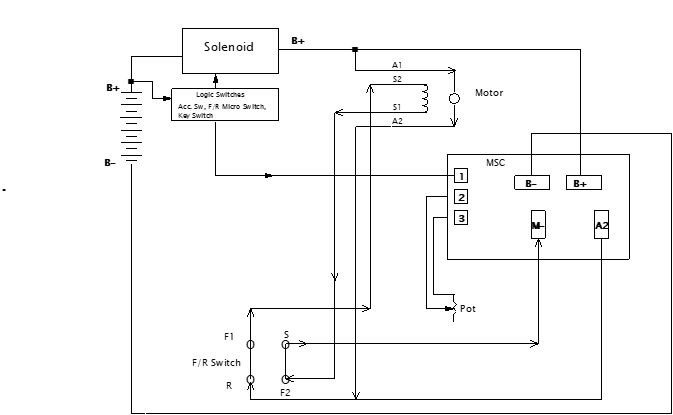

Many times, I am asked about the function of the M- terminal on the “series” type controllers used in the older golf carts. Everybody knows what the B+ and B- terminals are for and we’ll get to the A2 terminal (that may or may not even be on the controller) a little later, but for now we will focus on the M- terminal. To start with, here is a somewhat typical wiring diagram of a “series” cart that should help us understand what is going on:

Our discussion here assumes that all of the logic switches are happy (Key Switch is on, F/R Micro Switch is activated because the F/R Switch is in Forward, and the Accelerator Switch has been activated). Therefore, the Solenoid is energized, applying B+ to the B+ terminal of the controller and to A1 of the motor. It also assumes that the Throttle is working correctly so that its position indicates a valid reading between pins 2 and 3 of the controller. You will also notice that the connection between A2 on the controller and A2 on the motor is “dotted” on the diagram. That is because the connection may or may not even be there, depending on the system you have. It was originally included to provide a function called “plug braking” which never amounted to much anyway and is seldom included with newer controllers. So, just ignore it if you don’t have one.

With all of that in mind, the high energy flow of current through the motor circuitry is as follows:

From B+ at the output of the solenoid to A1 of the motor, through the armature of the motor to A2 and then to the F/R switch. Through the F/R switch contacts to S2 of the motor. Through the field windings of the motor to S1 and then to the F/R switch. Through the F/R switch to M- of the controller. Since all of these connections are in series, that makes M- the last thing in the circuit to B-. Its internal connection to B- is made by some switching (MOSFET) transistors. That is what completes the path from B+, through the controller to B-. The circuit is made complete (able to conduct current) only when M- starts to go in pulses toward B-.

If you were to connect an oscilloscope between the M- terminal of a series controller and B-, what you would see at first would be just a steady line at the B+ potential until the accelerator is depressed. As you moved the accelerator toward a higher speed, you would then see pulses going to the B- level. As the position of the accelerator continued to increase, the pulses would become wider and wider. Therefore, the “average” of their DC component would go lower and lower (the level at M- stays at B- for longer periods of time due to the wider, longer pulses). Now, these pulses are occurring at around 12 to 15 thousand times per second, so you would need an oscilloscope that would allow you to synchronize its sweep rate with the occurrence of the pulses. That way you could make them appear to stand still (so you could see and evaluate them). So, the farther the accelerator is advanced, the wider the pulses get. That is why the process is called Pulse Width Modulation (PWM). At full speed, the pulses are as wide as they can get (never coming back up to B+), So all you would see on the oscilloscope would be a constant line at the B- potential. So, when we look at M- with a DC meter, all we are seeing is the “average” value of what is really there. But, that “average” tracks with the widening of the pulses, so you really do get a good idea of what is going on (even though you can’t see the pulses). When M- reaches B- constantly (full acceleration), we say that the modulator has reached 100% modulation (also referred to as 100% duty cycle). All of this is assuming that the controller is working properly. Now let’s say there is a break in the “load” to the controller (like one of the wires is broken off of the motor or there is a burned contact in the F/R Switch or something similar). From my experience, most of the series type controllers will still operate internally without the completed load so, you can still get an accurate reading on M-, even without the load. Obviously, the cart won’t move because the current path through the motor has been broken. That is NOT true with all controllers. Through the years, I found some of them that would not function without a load. However, I discovered (through a long process of experimentation) that if I connected a 60 or 75 watt incandescent light bulb between M- and B-, it would suffice as enough of a load to get the modulator to work. That was important because it allowed me to pin down where the problem was actually coming from. For instance, let’s say that I had a wire broken off at the motor. That would constitute an “open” load. So, I would just put my light bulb between M- and B-, and advance the accelerator. If the bulb started to light when I moved the accelerator and continued to glow brighter as I advanced the accelerator, I knew that the controller was OK and that I needed to move on to the “load” side of the circuitry with my troubleshooting. I rigged up a 75 watt bulb in a socket that had leads sticking out the bottom. I then added alligator clips to the leads so that I could easily attach the bulb to B- and M-. It was an easy way to isolate the problem to the load, without even getting dirty. Knowing the controller was functional, I’d then be looking for a bad F/R Switch, motor wiring, stuck brush in the motor, etc. or anything that would could break the current path through the motor (that’s where you start getting dirty). All of the information in this post (and a bunch more) is covered in depth in the book that I wrote called Electric Golf Cart Repair 101 (and a half). For more information about the book, just follow this link: A Book About Electric Golf Cart Repair – Welcome to Golf Cart Stuff Hodgepodge

Ron Staley has published the following books, and you can get more information about them by just clicking on each title below:

Electric Golf Cart Repair 101 (and a half)

Techniques, Tips, Tools and Tales

Gas Golf Cart Repair 101 (and a half)

Techniques, Tips, Tools and Tales

4-Stroke Golf Cart Engines Explored

What Makes Them Tick

By an old Slot Machine Mechanic